Light Impurity Separator For Coarse Screening Process

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air

- Port:

- Qingdao, Tianjin, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100 Sets Per Month |

| Supply Ability: | 100 Sets Per Month |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | CE |

| Transportation: | Ocean,Land,Air |

| Port: | Qingdao,Tianjin,Shanghai |

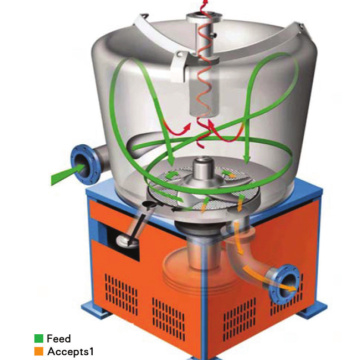

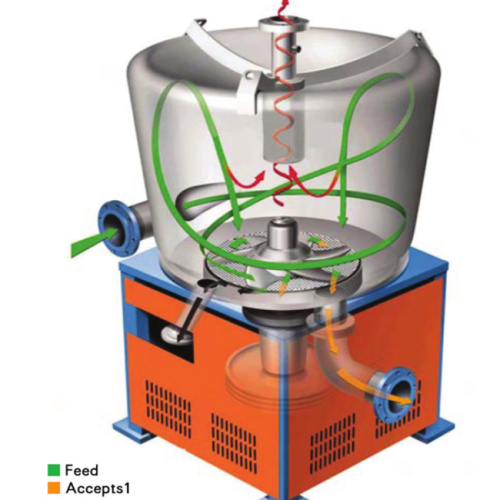

Light Impurity Separator Description

This float purger is distinctively utilized in removing light weight residue and tailing pulp in the coarse screening process of pulper stock preparation.The casing of this Separator is of inverted cone, and its concave top can form powerful vortex that produces a low pressure area on the top of casing to effectively collect and remove light impurities. Meanwhile, heavy impurities are sent to the outermost side of vortex by the centrifuge and then those heavy impurities sediment in the groove outside the screen plate. Later, those heavy impurities are removed continuously away from the float purger.

Main Technical Parameters

| Type | HT1 | HT2 | HT3 |

| Nominal Volume | 0.4 | 0.8 | 2 |

| Pressure of outflow pulp | 0.2-0.25 | ||

| Treating Consistency | 0.5-2 | ||

| Capacity of production | 35-45 | 65-85 | 110-140 |

| Power of motor | 30 | 55 | 110 |

| Dimensions(L*W*H): mm | 1825*910*1400 | 2600*1245*1955 | 3100*1700*2570 |

Features

The main body is an inverse conical design, concave top structure, can form a strong vortex, forming a low pressure area in the top center and getting the light impurities and discharge them outside effectively. Centrifugal force pushes heavy contaminatants into a tapered reject channel the periphety of the extraction plate, then discharge out of the machine continuously.

Related Keywords