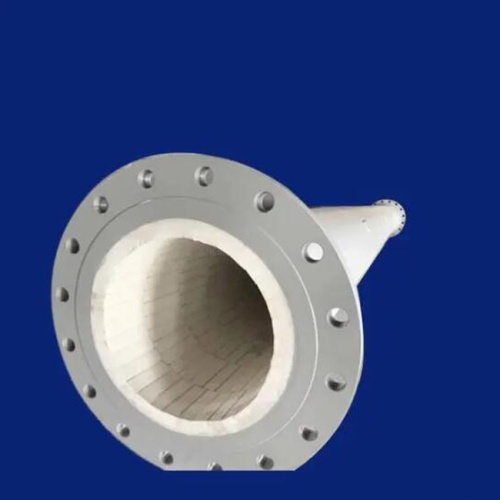

Ceramic Lined Cyclones for mining and Mineral Industry

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Tianjin, Qingdao, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| HS Code: | 8474100000 |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin,Qingdao,Shanghai |

The Ceramic Lined Cyclones is a special corundum ceramic made of AL2O3 as the main raw material and rare metal oxides as flux, which is baked at high temperature. Due to the high flow velocity of the cyclone, the wear is very serious. we provide 20mm and 25mm thick alumina wear-resistant ceramic lining plates used for cyclones, which can increase the life of the cyclone.

Since the cyclone body is a cylinder, the lower part is a cone, and the upper part also has an overflow box distribution box, etc., the wear-resistant ceramic lining plate must be processed into arcs, sectors, and different sizes of heads. We have provided more than 100 types of cyclone wear-resistant ceramic liners for customers to use.

Feature:

1.Special-sized ceramic blocks are designed according to the shapes of the cyclone cylinder, cone tube, underflow port tube, etc., with reasonable structure and small gaps;

2.The ceramic is 20mm or 25mm thick, dry-pressed, with high density and excellent wear resistance;

3.The wear-resistant ceramics are fixed by using high-strength modified adhesive and staggered bonding technology, without linear gaps, and are firmly bonded and will not fall off, suitable for harsh working conditions such as high impact, large flow or dynamic operation;

4.The inner wall is smooth, the material flows smoothly, and the height difference between ceramics is within 0.5mm, which can maintain the tangential velocity of the slurry in the cyclone, reduce energy loss, and obtain ideal classification effect.

Technical Data:

| Item | 92& Alumina Ceramic | 95% Alumina Ceramic |

| Al2O3 Content (%) | ≥92 | ≥95 |

| Hardness ( Mohs) | 9 | 9 |

| Density (g/cm3) | ≥3.63 | ≥3.68 |

| Water absorption (%) | ≤0.02 | ≤0.02 |

| Bending strength (Mpa) | 255 | 275 |

| Fracture toughness | 3.65 | 3.75 |

| Compressive Strength (Mpa) | ≥850 | ≥900 |

| Thermal Conductivity (W/M.K) | 16.8 | 16.8 |

Related Keywords