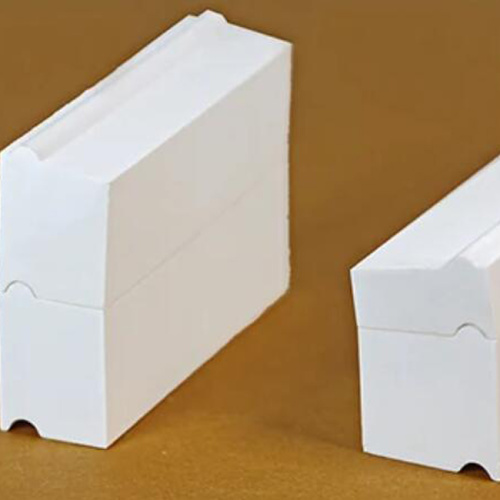

Ball Mill Wear Liners with Material 92% Alumina

- Min. Order:

- 1 Metric Ton

- Min. Order:

- 1 Metric Ton

- Port:

- Shanghai, Tianjin, Qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 400Ton/Month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,DDP,DDU |

| HS Code: | 6909120000 |

| Port: | Shanghai,Tianjin,Qingdao |

Description:

Wear-resistant ceramic lining bricks are an important part of the ball mill, and their main function is to protect the main part of the ball mill from wear.

In the ball mill, wear-resistant ceramic lining bricks are usually installed inside the cylinder, tightly fitting with the cylinder of the ball mill, thereby effectively protecting the cylinder from wear. At the same time, wear-resistant ceramic lining bricks can also reduce the impact and friction of materials on the cylinder, and extend the service life of the ball mill.

Wear-resistant ceramic lining bricks play a very important role in the ball mill due to their high hardness and high wear resistance. They can not only improve the efficiency of the ball mill, but also reduce production costs and improve the economic benefits of the enterprise.

Sepcification:

| 92 | 95 | T95 | ZTA | ZrO2 | |

| Density(g/cm³) | ≥3.6 | ≥3.65 | ≥3.7 | ≥4.15 | ≥5.9 |

| Al2O3(%) | ≥92% | ≥95% | ≥95% | ≥75% | / |

| ZrO2 +Y2O3 | / | / | / | ≥21% | ≥99.8% |

| Bending Strength(MPa) | ≥220 | ≥250 | ≥300 | ≥400 | ≥800 |

| Compressive Strength (MPa) | ≥1050 | ≥1300 | ≥1600 | ≥2000 | / |

| Fracture Toughness(MPa.m1/2) | ≥3.2 | ≥3.2 | ≥3.5 | ≥5.0 | ≥7.0 |

| Rockwell Hardness HRA | ≥82 | ≥85 | ≥88 | ≥90 | ≥88 |

| Vickers Hardness HV20(MPa) | ≥950 | ≥1000 | ≥1100 | ≥1400 | ≥1100 |

| Wear Volume(cm³) | ≤0.25 | ≤0.20 | ≤0.15 | ≤0.05 | ≤0.05 |

Related Keywords