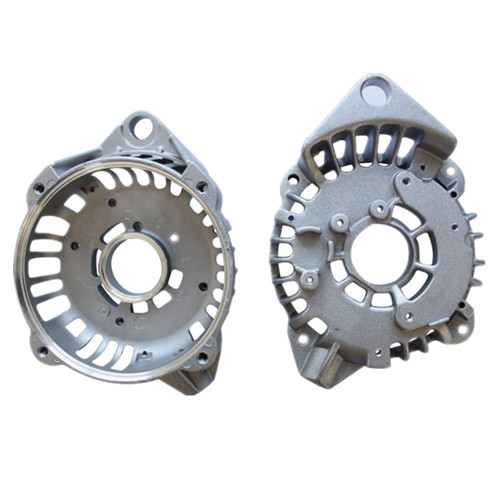

Aluminum Die Casting Auto Alternator Spare Parts

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA, CPT

- Min. Order:

- 500 Piece/Pieces

- Min. Order:

- 500 Piece/Pieces

- Delivery Time:

- 40 Days

- Transportation:

- Ocean, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| Certificate: | ISO 9001:2008 |

| Transportation: | Ocean,Air |

Aluminum Die Casting Auto Alternator Spare Parts

The aluminum die casting alternator spare parts, Aluminum Automotive Alternator Drive End Brackets, Die Casting Auto Electric Alternator Shell and Aluminum Casting Truck Alternator Housing are used for car, automobile or truck alternator. It's produced through aluminum die cast. The material ADC-12 ,A380 or as customers' requirements. It will be lighter, stronger and cheaper. The quality of our products are under control by ISO 9001:2008. Aluminum die casting automotive alternator drive end brackets have a wide range of application in auto equipments. Our aluminum alloy products also include Aluminum Casting Electric Motor Parts, Aluminum Casting Lighting Fixture, Aluminum Casting Camera Parts and Aluminum Telecommunication Part. The size and shape can be customized as your need, so various casting parts are available.

1) Surface Treatment

Shot blasting, Sand blasting, Painting,Polishing, Anodize, Chrome plating, Power coating, E-coating etc.

2) Machining

Lathe, CNC, drilling machine, milling machine, boring machine, planting machine, machining center etc.

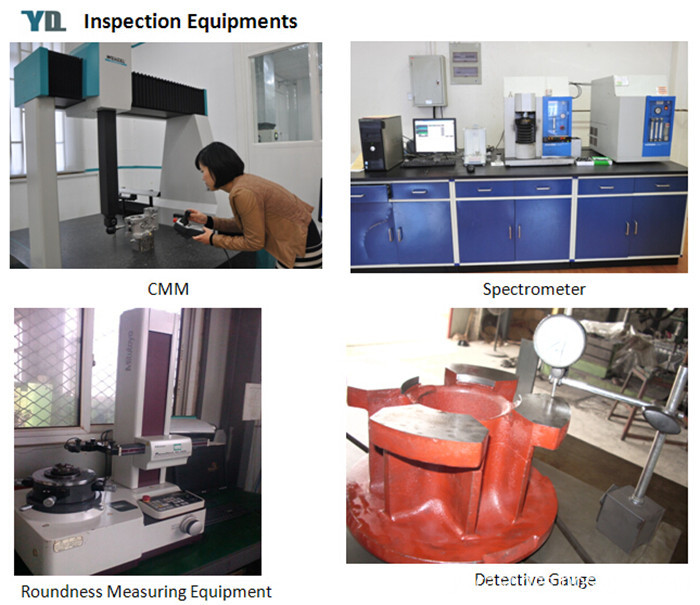

Inspection Equipments

Spectrum analysis instrument, metallurgical analysis, tensile strength tester, hardness tester, roughness tester, deflection tester, impact test machine, projector, altimeter, scale micrometer, pressure tester etc.

Advantages:

1) More than 10 years experience in casting industry.

2) We can print logo according to buyers' requirement

3) Qualified by ISO 9001:2008

4) We has exported to many countries,such as Italy, USA, Denmark, etc.

Related Keywords