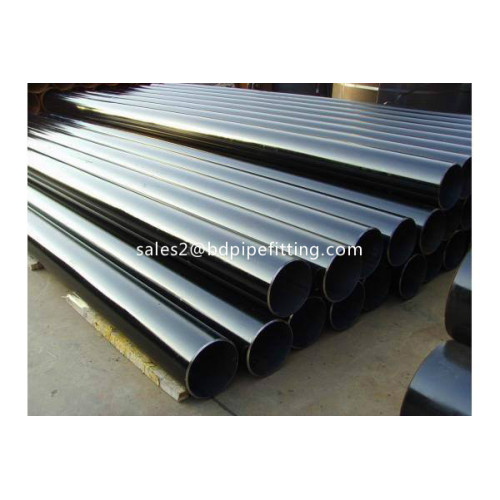

Carbon Steel Pipe ERW Welded Pipe

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 10 Meter

- Min. Order:

- 10 Meter

- Delivery Time:

- 20 Days

- Transportation:

- Ocean, Land, Air, Train/TNT/DHL

- Port:

- Tianijin New Port, Beijing Air Port, Cangzhou Train Station

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Cangzhou,China |

|---|---|

| Productivity: | 600T/month |

| Supply Ability: | 600T/month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO/CE/API |

| HS Code: | 73043990 |

| Transportation: | Ocean,Land,Air,Train/TNT/DHL |

| Port: | Tianijin New Port,Beijing Air Port,Cangzhou Train Station |

Carbon Steel Pipe ERW Welded Pipe

We offer a wide-range of carbon steel pipe products. The term carbon steel pipe is quite broad in scope and can be used to describe a wide range of metal tubular goods whose main alloying element is carbon. Although many of the same manufacturing principles apply to both carbon steel pipe and various similar alloy tubular goods, the focus of this narrative will be on the manufacturing process of mild carbon steel pipe goods commonly used for oil and gas as well as water transmission, structural applications, general purpose casing, piling, and mechanical components.

Carbon steel pipe starts out by arriving at the pipe mill in the form of either a billet (basically a large solid steel bar) or a coil (imagine a roll of toilet paper made out of steel). Depending on the manufacturing method used by the mill, these billets or coils will be processed to yield the finished end product. We will examine the various manufacturing methods used to make carbon steel pipe, but first let's look at how the carbon steel got here in the first place.

ELECTRIC RESISTANCE WELD (ERW)

Early carbon steel pipe producers employed a manufacturing method called butt-welding. The butt-welding process was quite elementary in that it merely rolled a piece of heated steel plate into tubular form and created a longitudinal weld through compression and direct heat. In 1922 the Fetz Moon Tube Company instituted the first continuous weld line where by rolled up coils of steel (again, imagine a toilet paper roll made of steel) could be unrolled, leveled, and continuously fed down a line of rolls which would slowly bend the steel into shape eventually to a point where the ends could be butt-welded. When the mill came to the end of a coil, they could simply weld it to the beginning of the next coil with little interruption to production. As industry called for tighter tolerances and better welds, the continuous butt-weld process gave way to electric resistance welding (ERW). ERW is quite similar to the continuous weld process in that coils of steel are leveled and fed down a line of forming rolls, but that is where the similarities end. During the ERW process the unrolled coils (skelp) are not heated and the longitudinal weld is created by way of an electric current. The weld is then electronically inspected for defects, normalized so as to maintain consistency with the rest of the steel, and cooled. At this point the pipe is sometimes resized and then cut, coated, and or tested to meet the desired specifications. ERW pipe typically holds much tighter tolerances and maintains surface and wall consistency much more than seamless carbon steel pipe. Common ERW specs include; API5LB, A53, and A500

Welded Carbon Pipe

Carbon Steel ERW Pipe

Carbon Steel ERW Pipe

Bangdong stocks and supplies a complete inventory of carbon steel pipe including ERW (Electric Resistance Welded) ,ranging in size from 1/8 inch to 60 inch OD. Along with commodity grades and sizes, we can supply many odd-ball & hard-to-find sizes. Ask about our pipe beveling, grooving, painting and coating options.

- Standard Grades: A53A, A53B, & API 5LB, API 5L X42, API 5L X52, API 5L X60, API 5L X65, X70

-

- Sizes: 1/8" – 60"

- Wall Sizes: 10, 20, STD, XH, and non schedule wall sizes

- Additional Services: Fusion Bond Epoxy, Galvanizing

Bangdong supplies Black Carbon Steel Pipes,A106 B Steel Pipe, Api5l Steel Pipe. We are engaged in offering a wide range of Seamless Pipe,seamless Heavy Wall Thickness Tubes. Our team members make use of high-grade steel to ensure their adherence with international standards and norms. The tubes offered by us are available in various thickness and diameters that meet the various requirements of our clients. Owing to their superior finish, dimensional accuracy and longer life, these tubes are widely used in sugar mills & distilleries, pumps and petrochemicals, cement and construction industries & steel plants.High Quality Api Tube in stock

Features:

Superior finish

Durability

Dimensionally accurate

Related Keywords