WELD NECK FLANGE ANSI B16.5

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air, Train/TNT/DHL

- Port:

- Tianjin New Port, Zhengzhou Train Station, Beijing Air Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Cangzhou,China |

|---|---|

| Productivity: | 1000pcs/month |

| Supply Ability: | 1000pcs/month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO/CE/API |

| HS Code: | 73079900 |

| Transportation: | Ocean,Land,Air,Train/TNT/DHL |

| Port: | Tianjin New Port,Zhengzhou Train Station,Beijing Air Port |

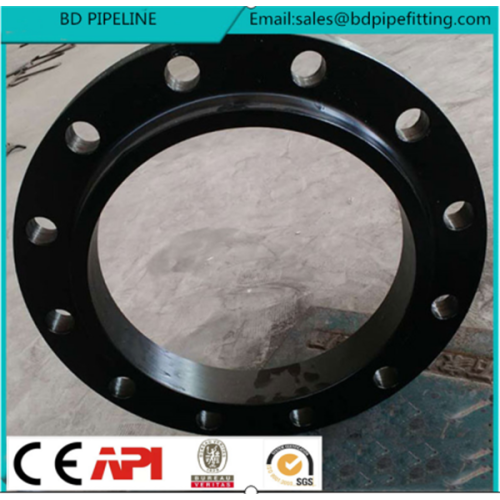

What is weld neck flange

A weld neck flanges (also known as a high-hub flange and tapered hub flange) is a type of steel flange. There are two designs. The regular type is used with pipes. The long type is unsuitable for pipes and is used in process plant.

A weld neck flange consists of a circular fitting with a protruding rim around the circumference. Generally machined from a forging, these flanges are typically butt welded to a pipe. The rim has a series of drilled holes that permit the flange to be affixed to another flange with bolts.

The Welding neck flanges is normally referred to as the high hub flange. It is designed to transfer stresses to the pipe, thereby reducing high stress concentrations at the base of the flange.

WN flange.6” CL150,SCH40,ASME B16.5/ASTM A105

Specification

|

Type |

: |

WN Forged Fitting & Flange |

|

Size |

: |

½” (15 NB) to 48″ (1200NB) |

|

Standard |

: |

ANSI B16.5, ANSI B16.47, ANSI B16.36, ANSI B16.48, BS 4504, EN1092, UNI 2277/2278, DIN, JIS, SABS1123, GOST-12820 |

|

Class |

: |

150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. |

|

DIN |

: |

DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673 |

|

BS |

: |

BS4504 , BS4504, BS1560, BS10 |

|

In Form |

: |

SORF, WNRF, BLRF, SWRF, LAP Joint, Threaded, Reducing, Spectacle, etc |

|

Specialize |

: |

As per drawing |

|

Coating/Surface Treatment |

: |

Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

|

Connection Type |

: |

Ring Type Joint, Lap-Joint Face, Raised Face Weld Neck Flange , Flat Face, Large Male-Female, Small Male-Female, Large Tongue & Groove, Small Tongue & Groove |

|

Flange Face Type |

: |

Flat Face (FF), Raise Face (RF), Ring Joint (RJT) |

|

Dimensions |

: |

ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

|

Packing |

: |

No Fumigate or Fumigate Plywood/Wood Pallet or Case |

|

Usage |

: |

Oil Field, Offshore, Water System, Shipbuilding, Natural Gas, Electric Power, Pipe Projects etc. |

Materials and Grade

Carbon Steel :

ASTM A105 ,A350 LF2

Alloy steel :

ASTM A182 F11/F12/F22/F5/F9/F91

Stainless Steel:

ASTM A182 F304/ F304L/ F316/ F316L/F310

1. Raw Material Raw Material Check Quantity Check Visual & Dimension Check

2. Material Inspection Chemical Analysis Check Preservation Analysis Certificate

3. Material Cutting Weight Measuring Cut Surface Check Marking

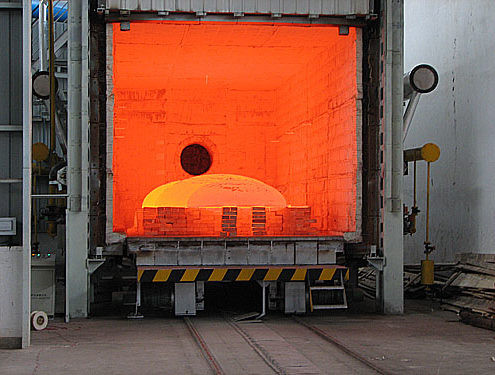

4. Flange forging Material Grade Check Weight Measuring Temperature Control

5. Heat Treatment Normalizing Tempering, Q.T Solution Treatment Mechanical Test

6. Forging Rolling Material Grade Check Weight Measuring Temperature Check Dimension Check

7.Final Inspection Dimension size inspect Visual Test Nondestructive Test

8. Rust Prevention Preserve Check Marking on the flange Marking on the flange

9. Well Packing Packing Spec. Check Packing Spec. Check Packing Inspection Delivery

Related Keywords