FORGED STEEL PIPE FITTINGS FORGED NIPPLE

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air, Train/TNT/DHL

- Port:

- Tianjin New Port, Beijing Air Port, Shanghai Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Cangzhou,China |

|---|---|

| Productivity: | 1000pcs/month |

| Supply Ability: | 1000pcs/month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO/CE/API |

| HS Code: | 73079300 |

| Transportation: | Ocean,Land,Air,Train/TNT/DHL |

| Port: | Tianjin New Port,Beijing Air Port,Shanghai Port |

What is Steel Nipple Fittings

Pipe nipples are a length of straight pipe with male threads on both ends. It is one of the most popular category of Thread Pipe Fitting.It is a connector or a coupling threaded on both ends. Pipe nipples are used to allow plumbing to be connected to a water heater or other plumbing. They are used to fit straight end hose or pipe. A combination of pipe nipples are recommended for low-pressure discharge and suction service for various compatible liquids and not for compressible products like air,nitrogen or steam.

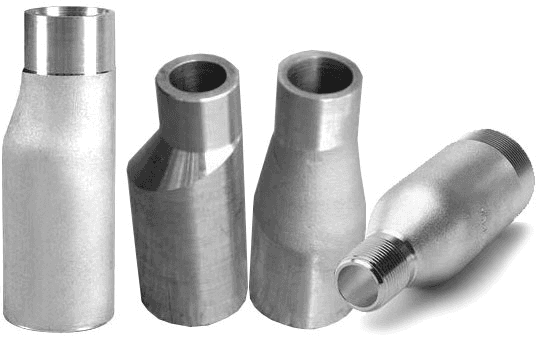

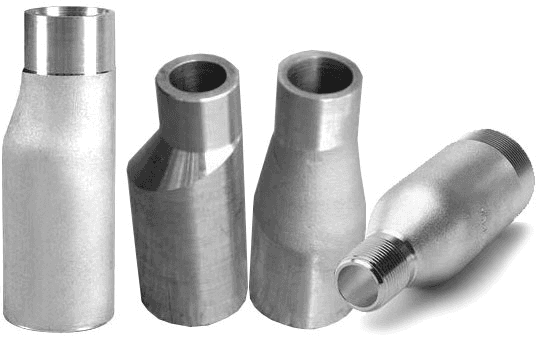

Concentric Nipple Carbon Steel Nipples

Specifications

Swage Nipple

Dimensions

ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 DIN2605 EN10253

Size

1/2″NB TO 4″NB IN

Class

3000 LBS, 6000 LBS, 9000 LBS

Type

Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT

Form

Forged socket &Threaded / Screwed Nipple, Concentric Swage Nipple, Eccentric Swage Nipple,Reducing Hex Nipple,Round Nipple

Value Added Services:

Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering

Production Grades:

Stainless Steel, Alloy Steel, Carbon Steel,

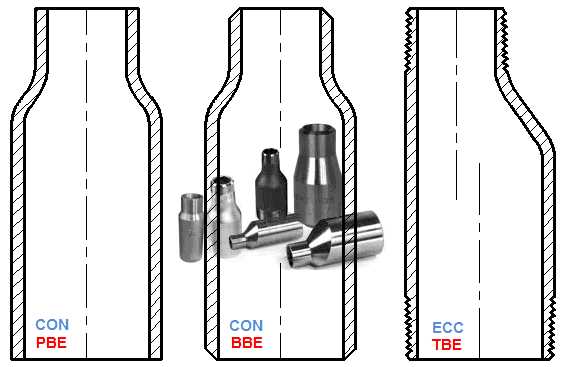

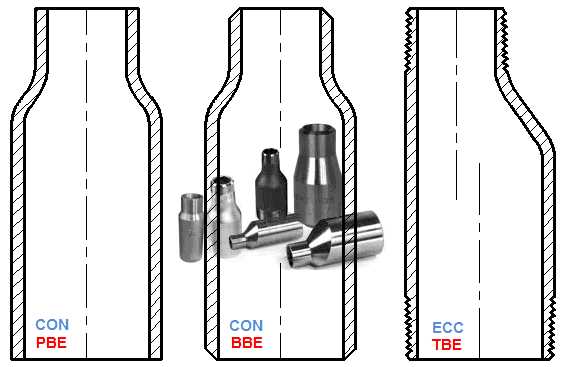

Surface Facing Types and Codes

Beveled large end-Plain small end BLE/PSE

Beveled large end-Thread small end BLE/TSE

Plain large end-Threaded small end PLE/TSE

Beveled both end BBE

Plain both end PBE

Threaded both end TBE

Materials and Grade

Carbon Steel :

ASTM A105 ,A350 LF2

Alloy steel :

ASTM A182 F11/F12/F22/F5/F9/F91

Stainless Steel:

ASTM A182 F304/ F304L/ F316/ F316L/F310

Industrial Processes

Die forging, Machining

Application

|

Dimensions |

ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 DIN2605 EN10253 |

|

Size |

1/2″NB TO 4″NB IN |

|

Class |

3000 LBS, 6000 LBS, 9000 LBS |

|

Type |

Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT |

|

Form |

Forged socket &Threaded / Screwed Nipple, Concentric Swage Nipple, Eccentric Swage Nipple,Reducing Hex Nipple,Round Nipple |

|

Value Added Services: |

Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering |

|

Production Grades: |

Stainless Steel, Alloy Steel, Carbon Steel, |

Beveled large end-Plain small end BLE/PSE

Beveled large end-Thread small end BLE/TSE

Plain large end-Threaded small end PLE/TSE

Beveled both end BBE

Plain both end PBE

Threaded both end TBE

Die forging, Machining

Related Keywords