ASME/ANSI B16.5 Class 150 TH Screwed Flanges

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 20 Days

- Transportation:

- Ocean, Land, Air, Train/TNT/DHL

- Port:

- Zhengzhou Train Station, Tianjin New Port, Beijing Air Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Cangzhou,China |

|---|---|

| Productivity: | 1000pcs/month |

| Supply Ability: | 1000pcs/month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO/CE/API |

| HS Code: | 73079900 |

| Transportation: | Ocean,Land,Air,Train/TNT/DHL |

| Port: | Zhengzhou Train Station,Tianjin New Port,Beijing Air Port |

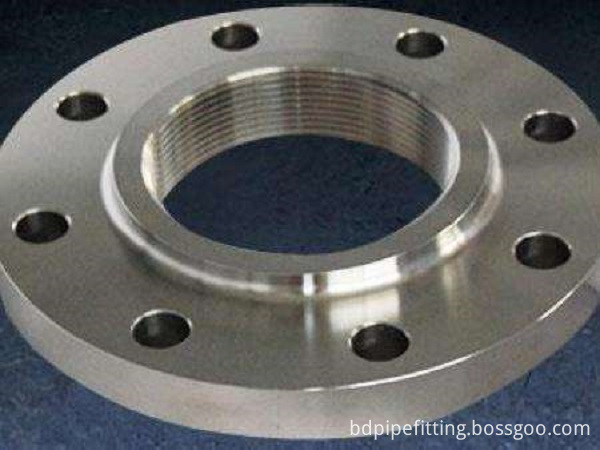

Screwed Flanges

This flange is referred to as either threaded or screwed. It is used to connect other threaded components in low pressure, non-critical applications.

The various types of thread flange are as follows:

- Plain Threaded Flanges

- Female Threaded Flanges

- Male Threaded Flanges

No welding is required.

Standards, Dimensions & Weight

- ANSI/ASME B16.5 Class 150 TH

- ASME/ANSI B16.5 Class 300 TH

- ASME/ANSI B16.5 Class 600 TH

- ASME/ANSI B16.5 Class 900 TH

- DIN 2565 PN6

- DIN 2566 PN10

Threaded Pipe Flange can be used in very high pressure services and their major advantage is that they can be assembled without welding.

Uses of threaded flanges :

- Thread Steel Fitting can be fitted to pipes of various sizes without welding and this is one chief benefit for which these flanges are highly demanded.

- They can be used in extremely high pressure applications, particularly at or near atmospheric temperature, where the necessary post weld heat treatment is not possible.

- They are ideal for small diameter piping applications.

- They are economical and time saving devices.

- These Threaded Fittings are normally designed for non-cyclic applications.

- The flanges are suitable to be used in applications where welding is hazardous.

- They can be used in highly explosive areas.

Material:

ASME/ANSI B16.5 Class 150 TH

| Nominal Pipe Size | Outside Diameter of Flange | Diameter of Raised Face | Thickness of Flanges Min. | Diameter of Hub | Length Through Hub | Thread Length Threaded Min. | Bore | Diameter of Bolt Circle | Diameter of Bolt Holes | Number of Bolts | Approximate Weight kgs |

| NPS | O | R | tf | X | Y | T | B | W | I | n | |

| 1/2 | 90 | 34.9 | 9.6 | 30 | 14 | 16 | 22.2 | 60.3 | 15.9 | 4 | 0.41 |

| 3/4 | 100 | 42.9 | 11.2 | 38 | 14 | 16 | 27.7 | 69.9 | 15.9 | 4 | 0.59 |

| 1 | 110 | 50.8 | 12.7 | 49 | 16 | 17 | 34.5 | 79.4 | 15.9 | 4 | 0.82 |

| 1 1/4 | 115 | 63.5 | 14.3 | 59 | 19 | 21 | 43.2 | 88.9 | 15.9 | 4 | 0.99 |

| 1 1/2 | 125 | 73.0 | 15.9 | 65 | 21 | 22 | 49.5 | 98.4 | 15.9 | 4 | 1.28 |

| 2 | 150 | 92.1 | 17.5 | 78 | 24 | 25 | 61.9 | 120.7 | 19.1 | 4 | 2.01 |

| 2 1/2 | 180 | 104.8 | 20.7 | 90 | 27 | 29 | 74.6 | 139.7 | 19.1 | 4 | 3.41 |

| 3 | 190 | 127.0 | 22.3 | 108 | 29 | 30 | 90.7 | 152.4 | 19.1 | 4 | 3.88 |

| 3 1/2 | 215 | 139.7 | 22.3 | 122 | 30 | 32 | 103.4 | 177.8 | 19.1 | 8 | 4.80 |

| 4 | 230 | 157.2 | 22.3 | 135 | 32 | 33 | 116.1 | 190.5 | 19.1 | 8 | 5.45 |

| 5 | 255 | 185.7 | 22.3 | 164 | 35 | 36 | 143.8 | 215.9 | 22.2 | 8 | 6.22 |

| 6 | 280 | 215.9 | 23.9 | 192 | 38 | 40 | 170.7 | 241.3 | 22.2 | 8 | 7.57 |

| 8 | 345 | 269.9 | 27.0 | 246 | 43 | 44 | 221.5 | 298.5 | 22.2 | 8 | 12.42 |

| 10 | 405 | 323.8 | 28.6 | 305 | 48 | 49 | 276.2 | 362.0 | 25.4 | 12 | 16.47 |

| 12 | 485 | 381.0 | 30.2 | 365 | 54 | 56 | 327.0 | 431.8 | 25.4 | 12 | 26.80 |

| 14 | 535 | 412.8 | 33.4 | 400 | 56 | 57 | 359.2 | 476.3 | 28.6 | 12 | 35.21 |

| 16 | 595 | 469.9 | 35.0 | 457 | 62 | 64 | 410.5 | 539.8 | 28.6 | 16 | 44.61 |

| 18 | 635 | 533.4 | 38.1 | 505 | 67 | 68 | 461.8 | 577.9 | 31.8 | 16 | 49.19 |

| 20 | 700 | 584.2 | 41.3 | 559 | 71 | 73 | 513.1 | 635.0 | 31.8 | 20 | 62.62 |

| 24 | 815 | 692.2 | 46.1 | 663 | 81 | 83 | 616.0 | 749.3 | 34.9 | 20 | 88.23 |

It also provides easy access for cleaning, inspection or modification. Flanges are usually welded or screwed. Pipe flanged joints are made by bolting together two flanges with a gasket between them to provide a seal.

Materials for Flanges

Pipe flanges are manufactured in all the different materials like stainless steel, cast iron, aluminium, brass, bronze, plastic etc. but the most used material is forged carbon steel and have machined surfaces.

In addition, flanges, like fittings and pipes, for specific purposes sometimes internally equipped with layers of materials of a completely different quality as the flanges themselves, which are "lined flanges".

The material of a flange, is basically set during the choice of the pipe, in most cases, a flange is of the same material as the pipe.

All flanges, discussed on this website fall under the ASME en ASTM standards, unless otherwise indicated. ASME B16.5 describes dimensions, dimensional tolerances etc. and ASTM the different material qualities.

.

.

Related Keywords