Farm Trailer Car Engine valve

- Payment Type:

- T/T, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1000 Piece/Pieces

- Min. Order:

- 1000 Piece/Pieces

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Tianjin, Guangzhou, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Hebei China |

|---|---|

| Productivity: | 3000000pcs/year |

| Supply Ability: | 100000pcs/month |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB |

| Certificate: | ISO/TS16949 |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin,Guangzhou,Shanghai |

Products Description

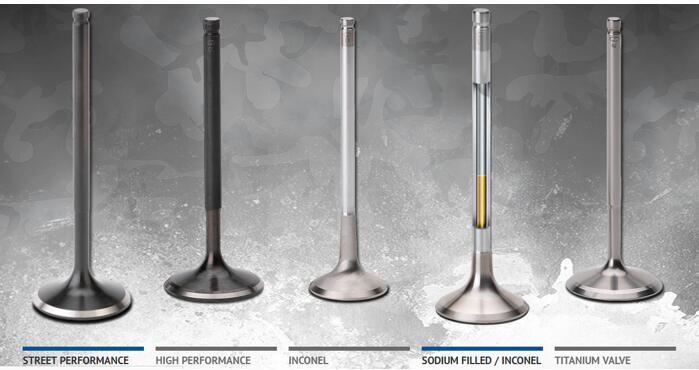

Specification: heavy duty Agricultural machinery diesel engine parts valve

An engine valve consists of a stem and a head, and it vaguely resembles a mushroom with its cap flipped upside down. With valves, precision is the key to optimal performance. It really is a modern miracle that the valve train -- valves, valve springs, rocker arms and guides -- can function day-in and day-out, thrashing about in their bath of oil, with rarely ever a hiccup. However, if the valves are seated even slightly off-kilter, or timed to open and close just the slightest bit off-specification, problems will result.

Harden process for valve seat's surface:high frequency quenching,high alloy welding,copying rolling etc.

Harden process for Valve stem :Chrome-plating,Nitriding,Spray welding etc.

Company Profile

Zhonghai shipping spare parts manufactory specializes in producing various engine valves since 1990,which collects together research and deveopment ,production and sales .our factory covers an area of 20000square meters ,with advanced technology and productiong process,strict testing measures to ensure better product quality ,after nearly 30years effort ,our factory has rich experience in manufacturing diesel engine valves and has become one of the biggest engine valve factories in China .

Advance Technology

Our factory owns more than 150 advanced special equipments,introduced technique from Japanese FUJI,using electric upsetting, double metal friction welding,blasting,chrome-plating,solution heat treatment,form grinding,polishing spiral,mirrow polishing,the valve surface using stellite or Ni-base alloy welding process, the stem using Nitrogen gas fasification process,high precision and wear resistance.

Each product will be 100%Tested before reach your hand,cooperate with us we will provide you with best quality and most competitive price.

Other Products

In order to serve customer well and meet their needs ,zhonghai factory had developed various engine parts,such as valve seat ,valve guide ,piston,piston pin,bearing and adjustable shim etc.

Packing and Delivery

Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters.

Related Keywords