Composite Building Panels

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1000 Square Meter

- Min. Order:

- 1000 Square Meter

- Delivery Time:

- 20 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 7,000,000 sqm per year |

| Supply Ability: | 7,000,000 sqm per year |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | CE, IS9001 |

| HS Code: | 760612 |

| Transportation: | Ocean,Land,Air |

| Port: | Qingdao |

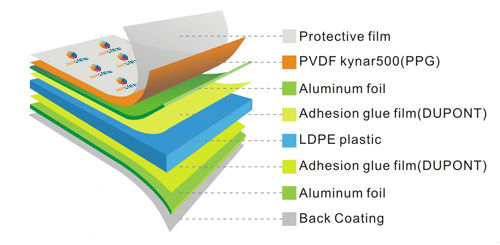

PVDF Aluminium Composite Panel coated with PVDF Kynar500 fluorocarbon coating to provide a low lasting ,durable finish for wall cladding applications.

The superb properties of this material boost one`s inspiration and offer architecture a whole new range of solution. Whether your project is a private home, a public building, a corporate headquarter or an office, a trading or industrial complex, or if you wants to create a new image, whether for petrol stations, car showrooms, banks or supermarket.

| PVDF ACP technical data: | ||

| Description | Test standard | PVDF |

| Thickness of coating | PVDF paint≧ 25um | 26um to 28 um |

| Coating Flexibility (T-bend) | PVDF paint≦2T | 2T |

| Color difference | ΔE≦2.0(Follow color sample) | ΔE〈2.0 |

| Pencil Hardness | ≧HB | ≧HB |

| Chemical Resistance |

5%HCL or5%NaOH test in 24 hourd- No change; ASTM D1308 |

No change |

| Coating Adhesion | ≧1Grade for 10*10 mm2 grdding Test | 1 grade |

| Resist Solvent | No charge for 200 times (MEK) | No change |

| Boiling Strength/Stripping Strength | Coating no tear off for 2 hour boiling | No tear off |

| Peeling Strength/ Shipping Strength |

Adverage≧7N/mm of 180oC peel for pane l with 0.5mm alu.skin |

7N/mm |

| Impact Test for Paint | 50Kg.cm impact-paint no split for panel | No split |

| Abrasion Resistance(L/Mil) | ASTM D968 | 44 |

| Temperature resistance |

-40℃ to +80℃ temperature without change of color tolerance ,paint peel off, peeling strength average dropprate ≦10% |

Change of gloss only. No paint peel off |

| Coefficient of Linear Thermal Expansion | 100℃ temperature difference | 2.4mm/m |

| Detergent Resistance(3%) | ASTM D2248 | No change |

| Humidity | ASTM D2247 | No change |

| Resistance(3000hrs,100%RH,100°F | ||

| Salt Spray Resistance (3000hrs, 5% salt | ASTM B117 | No change |

| Resistance Staining |

4000h radiate in 80㎡ in humidity condition, glossiness, deviation less grade2, color difference ≦4.0 |

No change |

| Specification: | ||

| Aluminium skin thickness | 0.12mm-0.50mm | |

| Total panel thickness | 2mm-10mm | |

| Panel Width | 1000mm,1220mm (regular), | |

| 1250mm,1300mm,1500mm,1550mm, | ||

| 1575mm,2000mm(maximum); | ||

| Panel Length | Up to 6500mm or according to your request | |

| Standard size | 1220mm(Width) ×2440mm(Length) | |

| Non-standard sizes depending on your offers | ||

| Standard color | 30kinds, special color available upon request | |

| Surface Treatment | PVDF Coating | |

| PE core Material: | Non-toxic and low-density Polyethylene | |

| Dimensional tolerance: | ||

| Panel Width | ± 2mm | |

| Panel Length | ± 3mm | |

| Panel Thickness | ±0.2mm | |

| Panel Diagonal | ≦5mm | |

| Aluminium sheet thickness | ± 0.02mm | |

Package & Loading

Related Keywords