Aluminium Composite Metal Panels

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1000 Square Meter

- Min. Order:

- 1000 Square Meter

- Delivery Time:

- 20 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 7,000,000 sqm per year |

| Supply Ability: | 7,000,000 sqm per year |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | CE, IS9001 |

| HS Code: | 760612 |

| Transportation: | Ocean,Land,Air |

| Port: | Qingdao |

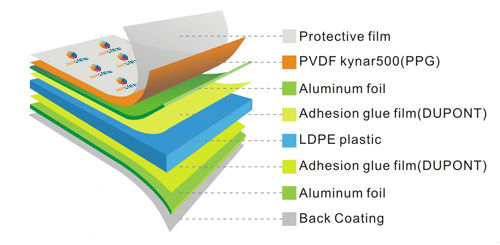

Aluminium Composite Metal Panels (ACM) coated with PVDF Kynar500 fluorocarbon coating to provide a low lasting ,durable finish for wall cladding applications.

consists of aluminum layers on both sides with a nontoxic polyethylene core (LDPE).

The superb properties of Kynar500 Aluminium Composite Panel boost one`s inspiration and offer architecture a whole new range of solution. Whether your project is a private home, a public building, a corporate headquarter or an office, a trading or industrial complex, or if you wants to create a new image, whether for petrol stations, car showrooms, banks or supermarket.

Kynar500 ACP is the key to unlock your dispay ideas and designs.

Application:

1) Constructional exterior curtain walls, Wall Panel are widely used in exhibition, stores, offices,

Banks, hotels, restaurants and apartments

2) Renovations of old buildings and movable houses

3) Wallboard and ceilings for tunnels

4) Material used for vehicle bodies, yachts and boat and subway

| PVDF ACP technical data: | ||

| Description | Test standard | PVDF |

| Thickness of coating | PVDF paint≧ 25um | 26um to 28 um |

| Coating Flexibility (T-bend) | PVDF paint≦2T | 2T |

| Color difference | ΔE≦2.0(Follow color sample) | ΔE〈2.0 |

| Pencil Hardness | ≧HB | ≧HB |

| Chemical Resistance |

5%HCL or5%NaOH test in 24 hourd- No change; ASTM D1308 |

No change |

| Coating Adhesion | ≧1Grade for 10*10 mm2 grdding Test | 1 grade |

| Resist Solvent | No charge for 200 times (MEK) | No change |

| Boiling Strength/Stripping Strength | Coating no tear off for 2 hour boiling | No tear off |

| Peeling Strength/ Shipping Strength |

Adverage≧7N/mm of 180oC peel for panel with 0.5mm alu.skin |

7N/mm |

| Impact Test for Paint | 50Kg.cm impact-paint no split for panel | No split |

| Abrasion Resistance(L/Mil) | ASTM D968 | 44 |

| Temperature resistance |

-40℃ to +80℃ temperature without change of color tolerance , paint peel off, peeling strength average dropprate ≦10% |

Change of gloss only. No paint peel off |

| Coefficient of Linear Thermal Expansion | 100℃ temperature difference | 2.4mm/m |

| Detergent Resistance(3%) | ASTM D2248 | No change |

| Humidity | ASTM D2247 | No change |

| Resistance(3000hrs,100%RH,100°F | ||

| Salt Spray Resistance (3000hrs, 5% salt | ASTM B117 | No change |

| Resistance Staining |

4000h radiate in 800W/㎡ in humidity condition, glossiness, deviation less grade2, color difference ≦4.0 |

No change |

| Specification: | ||

| Aluminium skin thickness | 0.12mm-0.50mm | |

| Total panel thickness | 2mm-10mm | |

| Panel Width | 1000mm,1220mm (regular), | |

| 1250mm,1300mm,1500mm,1550mm, | ||

| 1575mm,2000mm(maximum); | ||

| Panel Length | Up to 6500mm or according to your request | |

| Standard size | 1220mm(Width) ×2440mm(Length) | |

| Non-standard sizes depending on your offers | ||

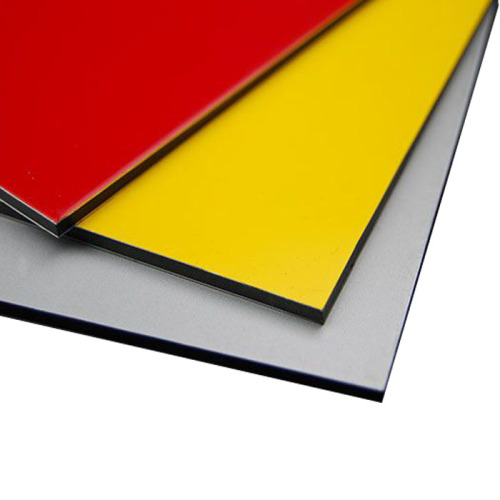

| Standard color | 30kinds, special color available upon request | |

| Surface Treatment | PVDF Coating | |

| PE core Material: | Non-toxic and low-density Polyethylene | |

| Dimensional tolerance: | ||

| Panel Width | ± 2mm | |

| Panel Length | ± 3mm | |

| Panel Thickness | ±0.2mm | |

| Panel Diagonal | ≦5mm | |

| Aluminium sheet thickness | ± 0.02mm | |

Package & Loading

Related Keywords