Small Slurry Pump AH

- Payment Type:

- L/C, T/T, Paypal, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA, CPT

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air, DHL

- Port:

- Tianjin, Dalian

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 10000 |

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| Certificate: | ISO, CE, SGS |

| HS Code: | 8413708100 |

| Transportation: | Ocean,Land,Air,DHL |

| Port: | Tianjin,Dalian |

The slurry pump widely used in river sand dredging work, construction site, mining plant and power station. Such as coase sand suction, fine tailings, mineral processing, gold mining beneficiation and so on.

Main Features

Outer Casing

Split outer casing halves of cast or ductile iron contain the wear liners and provide high operation pressure capabilities.

Impeller

The impeller may be either moulded elastomer or hard metal.Deep side sealing vanes relieve seal pressure and minimize recirculation.

Cast-in impeller threads are better suited for slurries.

Interchangeable hard metal and moulded elastomer liners.

Mating faces in hard metal liners are tapered to allow positive alignment during assembly and allow components to be easily removed for replacement.

Hydraulic seal rings give positive sealing between mating faces.

A large percentage of duties allow the use of the ce ntrifugal seal which eliminates the need of sealing water.

Gland shaft seal

A packed gland type shaft seal is also available and can be fitted with a low flow or a full flow flush seal water arrangement.

Shaft and bearing assembly

A large diameter shaft with a short overhang minimizes deflection and vibration.Heavy-duty roller bearings are housed in a removable bearing cartridge.

Pump Base

A minimum number if through bolts hold the pump casing to the frame .A means of impeller adjustment is provided in a convenient position below the bearing housing.

Introduction:

The pumps are designed as single-stage radial centrifugal pumps with volute casing, horizontal shaft, axial suction and tangential discharge pipe. They are applied for operation with abrasive water media with high concentration of solids.

The primary applications for the HAD metal slurry pumps are mill discharge, crusher slurry, sand and aggregate or any coarse solids or other severe, abrasive slurries especially in te copper, gold, iron ore, lead-zinc, coal or phosphate plants. The most dramatic savings will be in these applications, though savings will also be realized on find solids, like fine sand recovery or kaolin. The key advantage of the HAD metal slurry pumps is the 10% to 30% lower power, long even wear life and less pump downtime, which results in lowe cost-per-ton pumped, along with better cyclone separation.

|

Model -AH |

Allowable Max. Power (Kw) |

Capacity Q |

Head (м) |

Speed (r/min) |

Efficiency η% |

NPSH (m) |

|

|

m³/h |

l/s |

||||||

|

1.5/1B |

15 |

12.6-28.8 |

3.5-8 |

6-68 |

1200-3800 |

40 |

2-4 |

|

2/1.5B |

15 |

32.4-72 |

9-20 |

6-58 |

1200-3200 |

45 |

3.5-8 |

|

3/2C |

30 |

39.6-86.4 |

11-24 |

12-64 |

1300-2700 |

55 |

4-6 |

|

4/3C |

30 |

86.4-198 |

24-25 |

9-52 |

1000-2200 |

71 |

4-6 |

|

4/3D |

60 |

||||||

|

6/4D |

60 |

162-360 |

45-100 |

12-56 |

800-1550 |

65 |

5-8 |

|

6/4E |

120 |

||||||

|

8/6E |

120 |

360-828 |

100-230 |

10-61 |

500-1140 |

72 |

2-9 |

|

8/6R |

300 |

||||||

|

10/8ST |

560 |

612-1368 |

170-380 |

11-61 |

400-850 |

71 |

4-10 |

|

12/10ST |

560 |

936-1980 |

260-550 |

7-68 |

300-800 |

82 |

6 |

|

14/12ST |

560 |

1260-2772 |

350-770 |

13-63 |

300-600 |

77 |

3-10 |

|

16/14TU |

1200 |

1368-3060 |

380-850 |

11-63 |

250-550 |

79 |

4-10 |

Product Description

Type AH, AHR, slurry pumps are cantilevered, horizontal, centrifugal slurry pumps. They are designed for the handling highly abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industrial departments etc. The pumps of this type also may be installed in multistage series.

The frame plates for the type AH, AHR pumps have replaceable wear-resistant metal liners or rubber liners. The impellers are made of wear-resistant metal or rubber.

The shaft seals for type AH, AHR pumps may be adoptable of gland seal or expeller seal. The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications.

Product Application

Alumina,Copper mining,Iron ore,Gas oil,Coal ,Electric industry,Phosphate,Bauxite,Gold,Potash,

Wolfram,Water sewerage utilities,Sugar,Tobacco,Chemical fertilizer.

Certifications

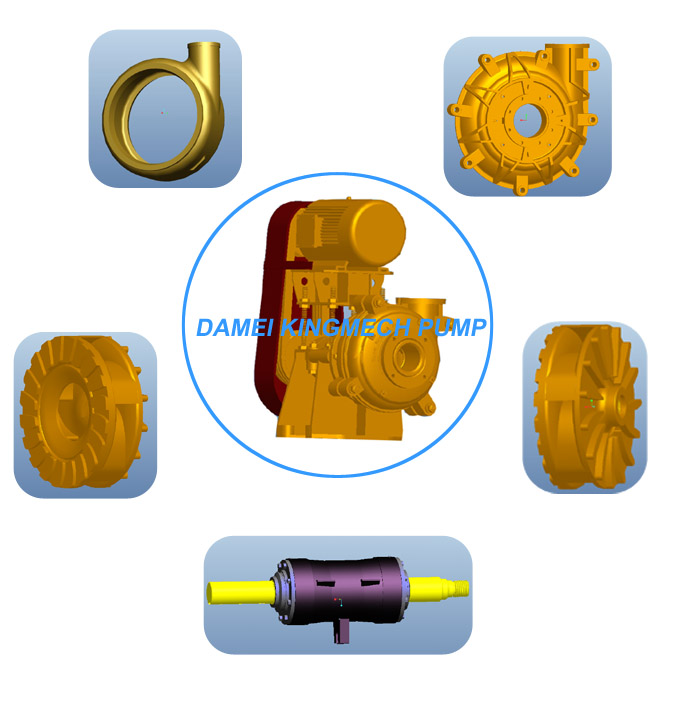

Pump Spare Parts

Name: Volute Liner

Brand: Damei

Original: China

Material: Cr27, Cr28, Rubber, Stainless steel, Gray iron, and so on.

Name: Impeller

Brand: Damei

Original: China

Material: Cr27, Cr28, Rubber, Stainless steel, Gray

iron, and so on.

Name: Frame plate liner

Brand: Damei

Original: China

Material: Cr27, Cr28, Rubber, Stainless steel, Gray

iron, and so on.

Name: Cover Plate Liner

Brand: Damei

Original: China

Material: Cr27, Cr28, Rubber, Stainless steel, Gray iron, and so on.

Technical

Three-dimensional diagram.

Damei Kingmech Pump with a professional technical engineer,we have a completed three -dimensional system

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Delivery

|

Packaging |

|

|

Size |

1050(L) * 660 (W) * 690 (D) |

|

Weight |

0.27 T |

|

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special reques |

Related Keywords