Heavy duty large capacity sand dredging pump DGD

- Payment Type:

- L/C, T/T, Paypal, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA, CPT, CIP

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air, DHL

- Port:

- Tianjin, Dalian

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 10000 |

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA,CPT,CIP |

| Certificate: | ISO, CE, SGS |

| HS Code: | 8413708100 |

| Transportation: | Ocean,Land,Air,DHL |

| Port: | Tianjin,Dalian |

Heavy duty large capacity sand dredging pump DGD

Suction dredges utilize a high-pressure dredging pump to suck up water, gravel and gold, and inject this material into a sluice through a header box. The header box dampens the rush of water and gravel so that it flows evenly into the sluice. The sluice then expels the worthless gravel and retains the gold. The sluice captures the gold behind the riffles. Generally speaking, a dredge that is designed to work with a sluice on a stand, in shallow water, is almost always equipped with a suction nozzle. The main advantage of the suction nozzle system is that you can dredge in very shallow water, and the suction nozzle can be completely out of the water without affecting the performance of the sluice.

DGD Series dredge sand pumps are designed to handle very large particles for gravel and dredging operations. This sand pumps are designed for continuous handling of the most difficult higher abrasive slurry, containing solids too large to be pumped by a standard slurry pump. DGD series dredge sand pumps are suitable for delivering slurry in mining, explosive sludge in metal melting, grudging in dredger and course of river and other fields.

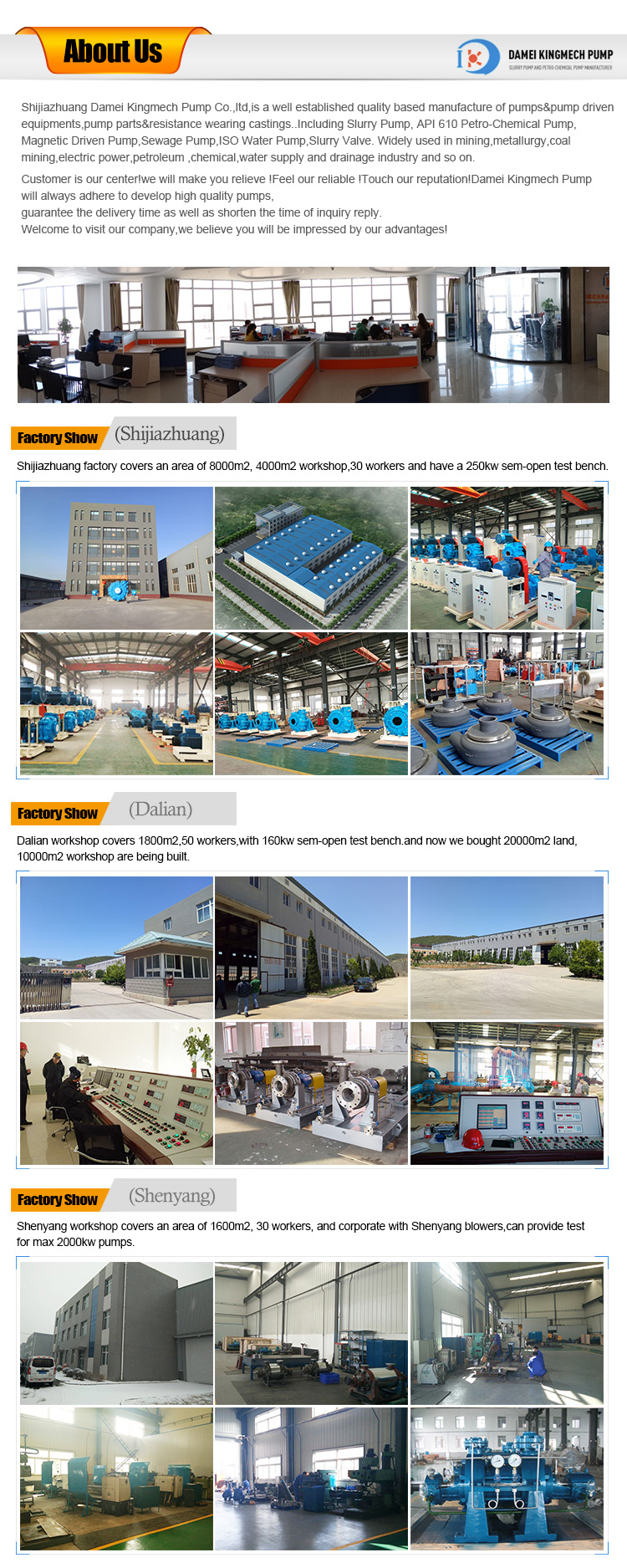

Damei kingmech Pump is the leading sand pump machine designer, manufacturer and exporter dedicated in supplying sand pumping equipment and dredging equipment to worldwide customers. We have more than 30 talented sand pumping experts and 15,000 square meters factory. More than 4 series 20 kinds of sand pumps, slurry pumps, gravel pumps, sand dredgers and related parts had been manufactured to satisfy your pumping requirements. Our main products include simple sand pump, slurry pump, gravel pump, submersible slurry pump, dredge pump, mining pumps, sand dredging pumps, small dredging equipment, dredger, dredger ship, submersible dredge, suction dredger, cutter dredger, mechanical cutter suction dredger, hydraulic cutter suction dredger, dredging equipment, sand pipe, floater, rubber hose. Product innovation and customer satisfaction are our continuous commitment to all our partners. We had been provided professional pump solutions and services to over 60 countries. Hope to become your pumping partners.

Type DGD gravel pumps are designed for continuous handling the most difficult higher abrasive slurries which contain too big solids to be pumped by common pump. They are suitable for delivering slurries in Mining, Explosive sludge in metal melting. Dredging in dredger and course of rivers, and other fields.

Construction of this pump is of single casing connected by means of clamp bands and wide wet passage. The wet parts are made of Ni-hard and high chromium abrasion-resistance alloys. The discharge direction of pump can be oriented in any direction of 360 degree. This type of pump possesses the advantages of easy installation and operation, good performance of NPSH and abrasion-resistance.

Performance range

Size:4-16inches

Capacity:36-5040m3/h

Head:5-80m

Material:Cr27,Cr28,

Seal:packing seal,expeller seal,mechnical seal.

More our pumps:

Slurry Pump

|--Heavy Duty Abrasive Slurry Pump

|--Low Abrasive Slurry Pump

|--Vertical Sump Slurry Pump

|--Dredge Slurry Pump For Sand And Gravel

|--Oil Lubrication High Head Slurry Pump

|--Multistage Slurry Pump

|--Submersible Slurry Pump

|--Vertical Froth Slurry Pump

|--Horizontal Froth Slurry Pump

|--Pump Spare Parts

API610 Pump

Magnetic Drive Pump

Sewage Pump

Clean Water Pump

|

Model -AH |

Allowable Max. Power (Kw) |

Capacity Q |

Head (м) |

Speed (r/min) |

Efficiency η% |

NPSH (m) |

|

|

m³/h |

l/s |

||||||

|

1.5/1B |

15 |

12.6-28.8 |

3.5-8 |

6-68 |

1200-3800 |

40 |

2-4 |

|

2/1.5B |

15 |

32.4-72 |

9-20 |

6-58 |

1200-3200 |

45 |

3.5-8 |

|

3/2C |

30 |

39.6-86.4 |

11-24 |

12-64 |

1300-2700 |

55 |

4-6 |

|

4/3C |

30 |

86.4-198 |

24-25 |

9-52 |

1000-2200 |

71 |

4-6 |

|

4/3D |

60 |

||||||

|

6/4D |

60 |

162-360 |

45-100 |

12-56 |

800-1550 |

65 |

5-8 |

|

6/4E |

120 |

||||||

|

8/6E |

120 |

360-828 |

100-230 |

10-61 |

500-1140 |

72 |

2-9 |

|

8/6R |

300 |

||||||

|

10/8ST |

560 |

612-1368 |

170-380 |

11-61 |

400-850 |

71 |

4-10 |

|

12/10ST |

560 |

936-1980 |

260-550 |

7-68 |

300-800 |

82 |

6 |

|

14/12ST |

560 |

1260-2772 |

350-770 |

13-63 |

300-600 |

77 |

3-10 |

|

16/14TU |

1200 |

1368-3060 |

380-850 |

11-63 |

250-550 |

79 |

4-10 |

Related Keywords