High Chrome Alloy/ Rubber Slurry Pump Spare Parts

- Payment Type:

- L/C, T/T, Paypal, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA, CPT, CIP

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air, DHL

- Port:

- Tianjin, Dalian

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Supply Ability: | 10000 |

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA,CPT,CIP |

| Certificate: | ISO, CE, SGS |

| HS Code: | 8413708100 |

| Transportation: | Ocean,Land,Air,DHL |

| Port: | Tianjin,Dalian |

Shijiazhuang damei kingmech pump co.,ltd is a professional manufacturer of slurry pumps And Pump Spare Parts, With about 30 years's experience.

Our Company Also can Accept OEM Order!

Our Products are widely used in mining, power, metallurgy, coal, dreading, building material and other Industrial lines to pump concentrate, tailings, sludge and other abrasive, high density slurries.

Impeller, liner, casing, base, expeller, exeller ring, shaft sleeve, seals.

Material:

Liners:

Standard: Chrome Alloy, Natural Rubber,

Options: Ferralium, Hastelloy C, 316 SS, W151, Polyurethane, Neoprene, Butyl, Viton, Nitrile, EPDM, Hypalon

Impellers:

Standard: Chrome Alloy, Natural Rubber,

Options: Ferralium, Hastelloy C, 316 SS, W151, Polyurethane, Neoprene, Butyl, Nitrile, Hypalon

Casing:

Standard: SG Iron

Options: SG Iron Various grades

Base:

Standard: SG Iron

Options: MS Fabricated, Cast Iron

Expeller:

Standard: Chrome Alloy Or SG Iron

Options: NI Resist, Ferralium, Hastelloy C, Polyurethane, 316 SS, W151

Shaft Sleeve

Standard: SG Iron

Options: EN56C, Ferralium, Hastelloy C, Titanium, 316 SS, 304 SS

Seals:

Standard: Rubber and Nitrile

Options: Ceramic, Stellite, Chrome Oxide, Nordel, Neoprene, Viton

Centrifugal Slurry Pump Parts Feature

1. Our pump impeller has excellent wear resistance, corrosion resistance Large passage area and perfect transportation ability. It can be easily Moved away and maintained.

2. The Frame plates have replaceable wear-resistant metal liners or rubberliners.

3. Advanced heat treatment technology is used to handle high-chrome Alloy and results of a compact micro-structure and high-quality product

4. All of the heat treatment process is computer controlled and recorded Automatically, to guarantee an accurate heat treatment process.

5. Good quality and low price; Any color you want; Endurable and timely Delivery

Product Description

1.The slurry pump spare parts are made of high chromium alloy which has superior wear and corrosive resistance.

2. Non-Standard slurry pump spare parts & Different size available.

Interchangeable Slurry Pump Parts , High Chrome Alloy Spare Parts , Slurry Pump Wet Parts , Interchangeable Slurry Pump , Interchangeable OEM Slurry Pump , Slurry Pump Parts , Vertical Slurry Pumps , Packing Seal Slurry Pumps

These parts are all standard parts, can fit to the slurry pumps perfectly.

We supply interchangeable metal and rubber parts for slurry pump series(AH, HH, SP, G, L, ZJ, M models).

various kind of centrifugal pump spare parts , such as Slurry Pump Rubber/metal Impeller,

Metal/ Natural rubber liners, Expeller, etc.

Pump Spare Parts

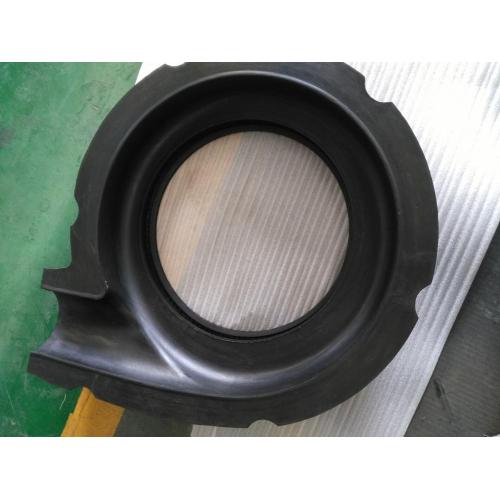

Name: Volute Liner

Brand: Damei

Original: China

Material: Cr27, Cr28, Rubber, Stainless steel, Gray iron, and so on.

Name: Impeller

Brand: Damei

Original: China

Material: Cr27, Cr28, Rubber, Stainless steel, Gray

iron, and so on.

Name: Frame plate liner

Brand: Damei

Original: China

Material: Cr27, Cr28, Rubber, Stainless steel, Gray

iron, and so on.

Name: Cover Plate Liner

Brand: Damei

Original: China

Material: Cr27, Cr28, Rubber, Stainless steel, Gray iron, and so on.

• Bearing assembly – a large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame.

• Liners – easily replaceable liners are bolted, not glued, to the casing for positive attachment and east of maintenance. Hard metal liners are completely interchangeable with pressure molded elastomer. Elastomer seal rings back all liner joints.

• Casing – Casing halves of cast or ductile iron with external reinforcing ribs provide high operating pressure capabilities and an extra measure of safety.

• Impeller – front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available.

• Throat bush – wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal.

• One-piece frame – a very robust one-piece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance.

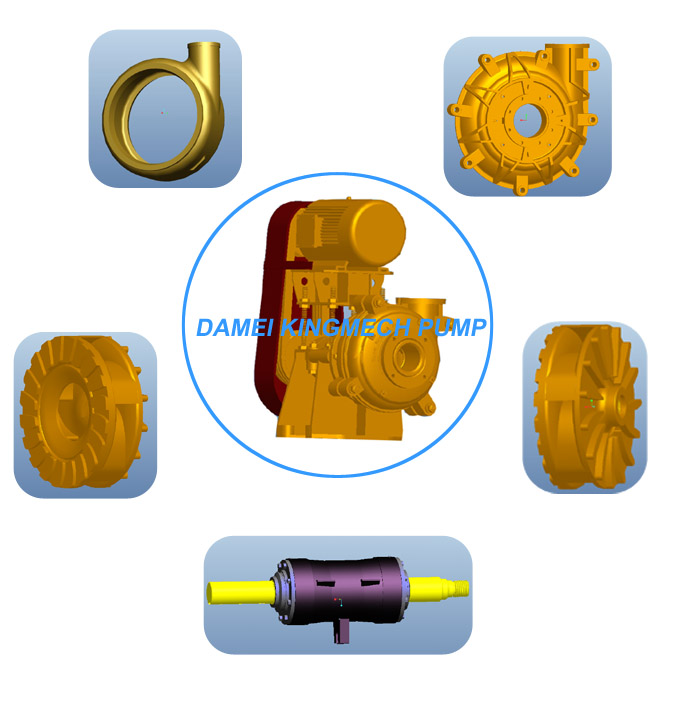

Technical

Three-dimensional diagram.

Damei Kingmech Pump with a professional technical engineer,we have a completed three -dimensional system

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Delivery

|

Packaging |

|

|

Size |

(L) * (W) * (D) |

|

Weight |

T |

|

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special reques |

Related Keywords