D20 F127 laser lens

- Transportation:

- Ocean, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Productivity: | 4000 |

| Supply Ability: | 4000 |

| Transportation: | Ocean,Air |

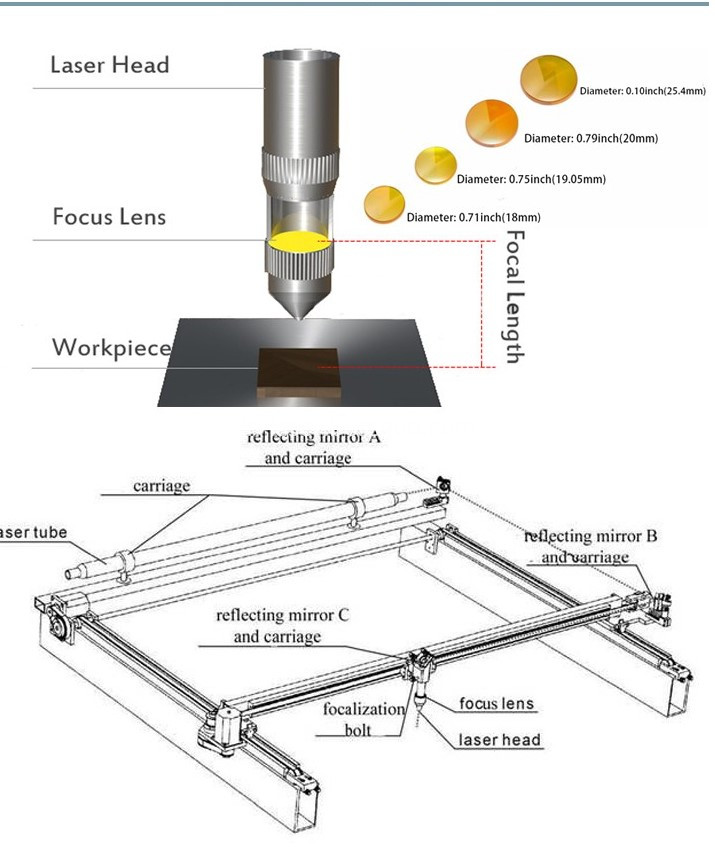

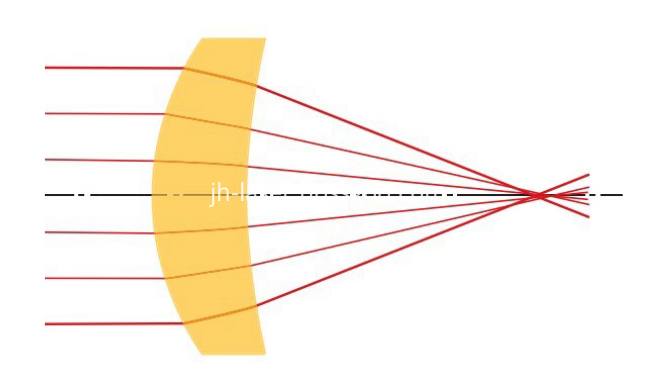

As a most economical transmission focus components, lens are widely used in some industries, such as laser heat treatment, welding, cutting and infrared radiation collection, in order to obtain satisfactory performance and achieve the purpose that the surface of the lens should be towards the direction of imputed light beam towards the conjugate distance the longer end. The production of lenses can withstand the high power density, and surface film layer is firm, not easy to fall off, wiping resistance. The import of ZnSe double plating antireflection Mo, reached 99.5% in CO2 laser industry common working band 10.6 um transmittance can. From two angles of diffraction and aberration optimization design, introduced the actual focusing spot diameter to series of products in the same focal length minimum condition. Can also be based on user requirements of different focal length, focal length, lens aperture, the diameter of the incident light after a separate design and processing

|

General requirements for lens fabrication |

|

Material: |

cvdZnSe(USA) |

|

Wavelength: |

10.6μm |

|

Focal length tolerance: |

±1% |

|

Form tolerance: |

+0.0/-0.1mm |

|

Thickness tolerance: |

±0.1mm |

|

Type: |

λ/2 632.8nm |

|

Finish: |

20-10 |

|

Eccentric: |

<3' |

|

Effective aperture: |

>90% |

|

The down side: |

<0.2×45° |

|

Coating: |

10.6um Antireflective coating,8-14umBroadband antireflective coating |

|

Type:Moon |

|

Mode |

Diameter |

Focal length |

Thickness |

Type |

Material |

|||

|

mm |

inch |

mm |

inch |

mm |

inch |

|||

|

JH-D12 F50 |

12/12.7 |

0.47/0.5 |

50.8 |

2 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

|

JH-D15 F38 |

15 |

0.59 |

38.1 |

1.5 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

|

JH-D15 F50 |

50.8 |

2 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D15 F63 |

63.5 |

2.5 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D15 F75 |

75 |

3 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D15 F100 |

101.6 |

4 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D15 F127 |

127 |

5 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D15 F190 |

190.5 |

7.5 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D18 F38 |

18 |

0.71 |

38.1 |

1.5 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

|

JH-D18 F50 |

50.8 |

2 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D18 F63 |

63.5 |

2.5 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D18 F75 |

75 |

3 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D18 F100 |

101.6 |

4 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D18 F127 |

127 |

5 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D18 F190 |

190.5 |

7.5 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D19 F38 |

19.05 |

0.75 |

38.1 |

1.5 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

|

JH-D19 F50 |

50.8 |

2 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D19 F63 |

63.5 |

2.5 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D19 F75 |

75 |

3 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D19 F100 |

101.6 |

4 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D19 F127 |

127 |

5 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D19 F190 |

190.5 |

7.5 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D20 F38 |

20 |

0.79 |

38.1 |

1.5 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

|

JH-D20 F50 |

50.8 |

2 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D20 F63 |

63.5 |

2.5 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D20 F76.2 |

76.2 |

3 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D20 F100 |

101.6 |

4 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D20 F127 |

127 |

5 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D20 F190 |

190.5 |

7.5 |

2.5 |

0.10 |

M |

cvdZnSe(USA) |

||

|

JH-D25 F38 |

25.4 |

1.00 |

38.1 |

1.5 |

3 |

0.12 |

M |

cvdZnSe(USA) |

|

JH-D25 F50 |

50.8 |

2 |

3 |

0.12 |

M |

cvdZnSe(USA) |

||

|

JH-D25 F63 |

63.5 |

2.5 |

3 |

0.12 |

M |

cvdZnSe(USA) |

||

|

JH-D25 F76.2 |

25.4 |

1.00 |

76.2 |

3 |

3 |

0.12 |

M |

cvdZnSe(USA) |

|

JH-D25 F100 |

25.4 |

1.00 |

101.6 |

4 |

3 |

0.12 |

M |

cvdZnSe(USA) |

|

JH-D25 F127 |

25.4 |

1.00 |

127 |

5 |

3 |

0.12 |

M |

cvdZnSe(USA) |

|

JH-D28 F38 |

28 |

1.1 |

38.1 |

1.5 |

4 |

0.16 |

M |

cvdZnSe(USA) |

|

JH-D28 F50 |

50.8 |

2 |

4 |

0.16 |

M |

cvdZnSe(USA) |

||

|

JH-D28 F63 |

63.5 |

2.5 |

4 |

0.16 |

M |

cvdZnSe(USA) |

||

|

JH-D28 F76.2 |

28 |

1.1 |

76.2 |

3 |

4 |

0.16 |

M |

cvdZnSe(USA) |

|

JH-D28 F100 |

28 |

1.1 |

101.6 |

4 |

4 |

0.16 |

M |

cvdZnSe(USA) |

|

JH-D28 F127 |

28 |

1.1 |

127 |

5 |

4 |

0.16 |

M |

cvdZnSe(USA) |

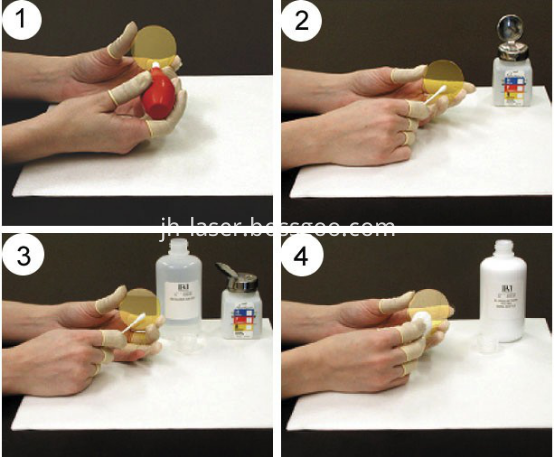

3. cleaning lens

First step :clean the soft light pollutants (dust, the floe content)

Second step :gently clean light pollutants (dust, fingerprint)

The third step : clean the medium pollutants moderately (saliva, oil droplets)

If this step can't remove dirt, continue to step 4.

The fifth step : the detection of cleaned lens

Clean lens, must be very careful, before cleaning, please look at the following notice:

1. Take lens must wear gloves or rubber gloves, because the dirt and oil droplets on the hand can contaminate the lens, cause performance decline.

2. Don't use any tool to take the lens, such as tweezers, etc.

3. Put the lens on paper, in order to avoid damage.

4. Don't put the glasses on rough or hard surface, infrared lens is easy to scrape.

5. Pure gold or pure copper surface don't clean and touch.

Related Keywords