2'' Rubber Slurry Pumps with motor over base

-

$2257.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express, Express

- Port:

- Tianjin, Qingdao, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 200sets per month |

| Supply Ability: | 200Sets per month |

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,Express Delivery |

| Certificate: | ISO , CE |

| HS Code: | 8413709990 |

| Transportation: | Ocean,Land,Air,Express,Express |

| Port: | Tianjin,Qingdao,Guangzhou |

2'' Rubber Lined Slurry Pumps with motor over the base

We have rubber material such as R08,R12,R26,R33,R38,R55,S03,S12,S31,S21,S42,S51,S52 etc.

Bearing assembly -- A large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame.

Liners -- Easily replaceable liners are bolted, not glued, to the casing for positive attachment and ease of maintenance. Hard metal liners are completely interchangeable with pressure molded elastomers. Elastomer seal rings back all liner joints.

Casing -- Casing halves of cast or ductile iron with external reinforcing ribs provide high operating pressure capabilities and an extra measure of safety.

Impeller -- Front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available.

Throatbush -- Wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal.

One-piece frame -- A very robust one-piece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance.

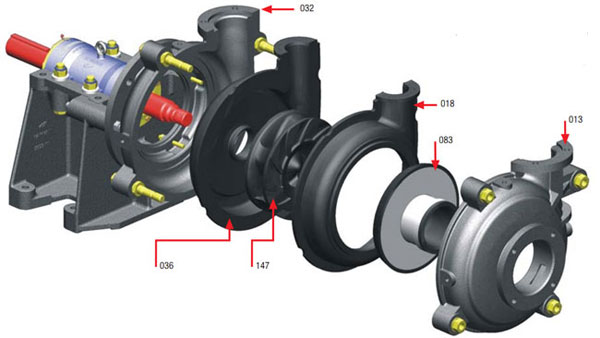

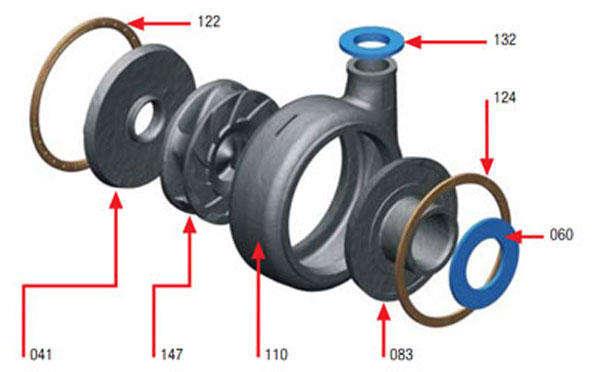

Construction Drawing

Elastomer parts

Metal Lined

Main Part Number At The Drawing

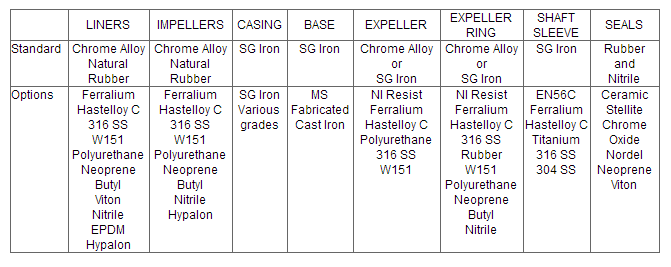

Materials of Construction

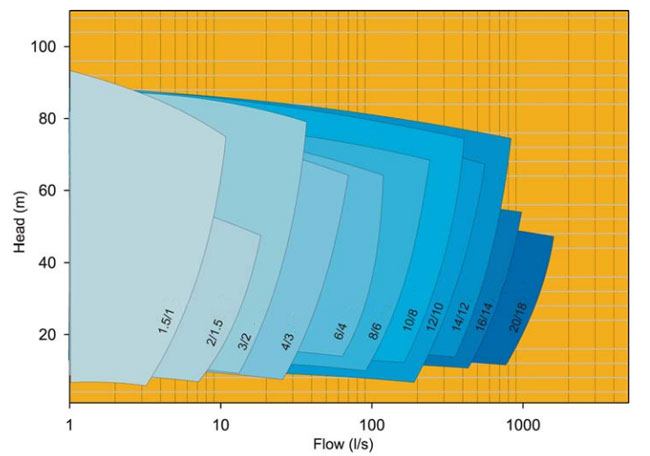

NP-AH(R) PUMP SELECTION CHART

NP-AH SLURRY PUMP PERFORMANCE PARAMETERS

Type

Allowable Mating Max.Power(Kw)

Clear Water Performance

Impeller

Capacity/Q m³/hr

Head/m

Speed/rpm

Max Efficiency/%

NPSH/m

Nos of Vane

Impeller Diameter/mm

1.5/1NAHR

15

10.8--25.2

7-52

1400--3400

35

2-4

3

152

2/1.5NAHR

15

25.2-54

5.5-41

1000--2600

50

2.5-5

5

178

3/2NAHR

30

36-75.6

13-39

1300--2100

55

2-4

5

213

4/3NAHR

30

79.2-180

5-34.5

800-1800

59

3-5

5

245

6/4NAHR

60

144-324

12-45

800-1350

65

3-5

5

365

8/6NAHR

300

324-720

7-49

400-1000

65

5-10

5

510

10/8NAHR

560

540--1188

12-50

400-750

75

4-12

5

686

12/10NAHR

560

720--1620

7--45

300-650

80

2.5-7.5

5

762

14/12NAHR

560

1152--2520

13--44

300-500

79

3-8

5

965

16/14NAHR

1200

1200-3000

11-42

250-450

82

4-9

5

1067

20/18NAHR

1200

1800-4000

12--44

200-350

82

5-10

5

1370

Product Overviews:

Ahr Horizontal slurry Pump with motor overside,there are 4 types of drive types: CVz,DCz,ZVz,CRz

Ahr Rubber Slurry Pump

Cvz Horizontal Mining Slurry Pump

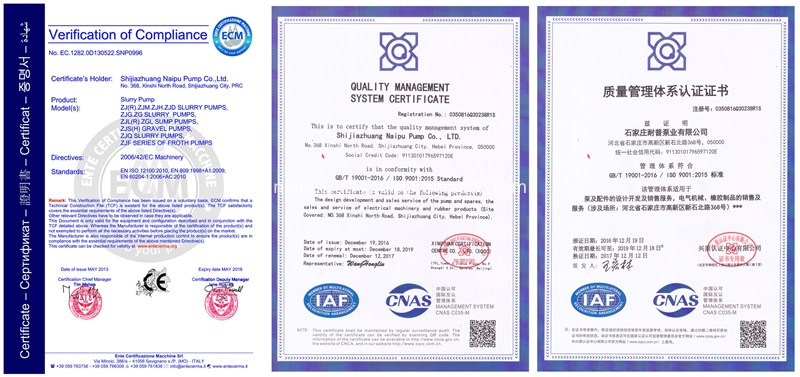

Certificate:

Our Workshop show:

NAIPU PUMP is a whole processing company, Start from Modeling Workshop,Casting Workshop,Heat treatment Workshop,Machining Workshop ,Assembly Workshop and Pump Testing Workshop are all by us. So we are modernization and integrated company to satisfy the requirement of the changing needs of market.

Quality Control:

As a professional pump manufacturer,we always stick to the principle of technology and quality comes first. At NAIPU PUMP, we strictly adhere to the ISO9001 Standard and CE Certificate and other industry standards as requests.

We set various check points along the whole production line,which throughout Raw Material,Charging Material,Surface and Heat Treatment checking,Material Analysis,Spare Testing and Pump Testing etc.

Application On Site:

This series centrifugal slurry pumps used as, Booster pump, De-Watering Screen Pump, Tailings Pump, Metboom Pump, Feedprep Pump, Scavenger Feed Pump, Re-Cleaner Pump, Ball mill discharge Pump, Ruffer Feed Pump, Transfer to feedprep Pump, Metboom Return Pump, Thickner Underflow Pump, Thickner Tailings Pump, Thickner Underflow Pump, Rinse Pump, Dilute Pump, Re-Cleaner Pump, Rougher Feed Pump, Tailings booster Pump, Mill slurry Pump, Mill feed water Pump, Disc filter basin flushing Pump, Mixing tank slurry Pump, Gas cleaning slurry Pump, Windbox slurry Pump, Pellet hand etc.

Contact Details:

Shijiazhuang Naipu Pump Co.,Ltd.

Whatsapp:+86-13623314232

Contact Person: Karen Tan

Skype: karen_naipump

Related Keywords