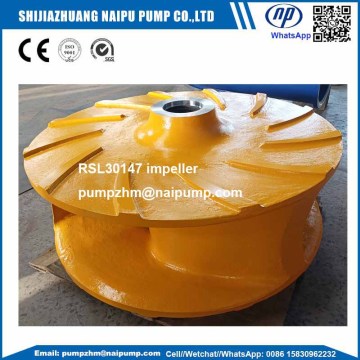

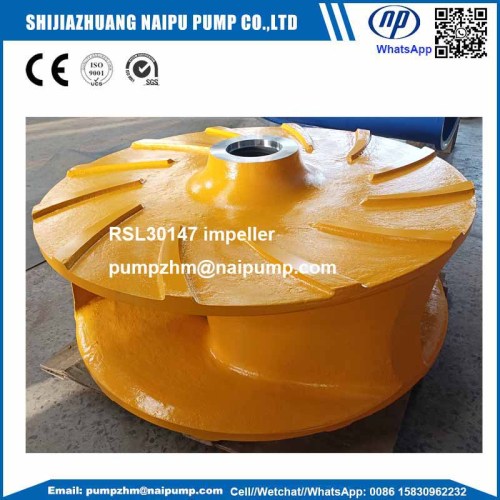

RSL30147A05 Impeller for 300FF-L Light Duty Slurry Pump

-

$2000.00≥1 Piece/Pieces

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express, Express

- Port:

- Tianjin, Qingdao, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 200sets per month |

| Supply Ability: | 200Sets per month |

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,Express Delivery |

| Certificate: | ISO , CE |

| HS Code: | 8413709990 |

| Transportation: | Ocean,Land,Air,Express,Express |

| Port: | Tianjin,Qingdao,Guangzhou |

RSL30147A05 Impeller , RSL30147A05 high chrome impellers, RSL30147 A05 slurry pump impellers, OEM impellers, RSL30147 IMPELLERS, RSL30147 slurry pump impellers, Impeller RSL30147A05 is suit for Metal Lined Slurry Pump 300FF-L.spare parts for 300FF-L Horizontal Slurry Pumps.

metal spare parts: Impeller RSL30147A05, Frame Plate Liner Insert SL30041MA05, Volute Liner SL30110A05, Throat Bush SL30083MA05, Bearing Assembly FFRS005M, Stuffing Box RSL30078D21 and Shaft Sleeve RS076C21, etc

Naipu's 300S-L Light Slurry Pump Impellers RSL30147A05 are large diameter, slow turning, high efficiency impellers (up to 90%+) result in maximum wear life and lower operating costs.

The 300S-L Light Duty Slurry Pump provides the widest range of hydraulics, it is perfect for the laboratory or in demonstration plants.

L Series Pump Design Features:

√ Heavy duty construction with through-bolt design provides ease of maintenance and minimal downtime.

√ Ductile iron fully lined casing provides durability, strength, safety, and long service life.

√ Large, open internal passages designed to reduce internal velocities, maximize wear life and lower operating costs.

√ Thick elastomer or alloy bolt-in liners provide superior corrosion resistance plus offer ease of liner change-out and interchangeability to reduce overall maintenance costs and maximize wear life.

√ Designed for rugged duties while offering excellent efficiencies.

√ Minimal shaft/impeller overhang reduces shaft deflection and increases packing life.

√ Cartridge-style bearing assembly allows for maintenance in a clean environment without removal of the pump, resulting in reliable operation and prolonged bearing life.

√ Grease or oil lubrication bearing assembly options offer ease of maintenance and reduced downtime.

√ Full flush gland, low flow, and dry running centrifugal seals reduce flush water usage minimizing pump operating costs.

√ Mechanical seals reduce flush water usage, minimizing pump operating costs.

L Series Slurry Pump Impellers:

|

Impeller Code |

L Slurry Pump |

Slurry Pump Materials Code |

|

175056 |

20A-L |

A05, A06, A07, A33, A49, A51, A61, etc |

|

32056 |

50B-L |

A05, A06, A07, A33, A49, A51, A61, etc |

|

43056 |

75C-L |

A05, A06, A07, A33, A49, A51, A61, etc |

|

64056 |

100D-L |

A05, A06, A07, A33, A49, A51, A61, etc |

|

86056 |

150E-L |

A05, A06, A07, A33, A49, A51, A61, etc |

|

108056 |

200E-L |

A05, A06, A07, A33, A49, A51, A61, etc |

|

SL30147 |

300S-L |

A05, A06, A07, A33, A49, A51, A61, etc |

|

SL35147 |

350S-L |

A05, A06, A07, A33, A49, A51, A61, etc |

|

STL40147 |

400ST-L |

A05, A06, A07, A33, A49, A51, A61, etc |

|

STL45147 |

450ST-L |

A05, A06, A07, A33, A49, A51, A61, etc |

|

TUL55147 |

550TU-L |

A05, A06, A07, A33, A49, A51, A61, etc |

Related Keywords