Urethane Parts For Slurry Pumps

-

$123.00≥1 Piece/Pieces

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express, Express

- Port:

- Tianjin, Qingdao, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 200sets per month |

| Supply Ability: | 200Sets per month |

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,Express Delivery |

| Certificate: | ISO , CE |

| HS Code: | 8413709990 |

| Transportation: | Ocean,Land,Air,Express,Express |

| Port: | Tianjin,Qingdao,Guangzhou |

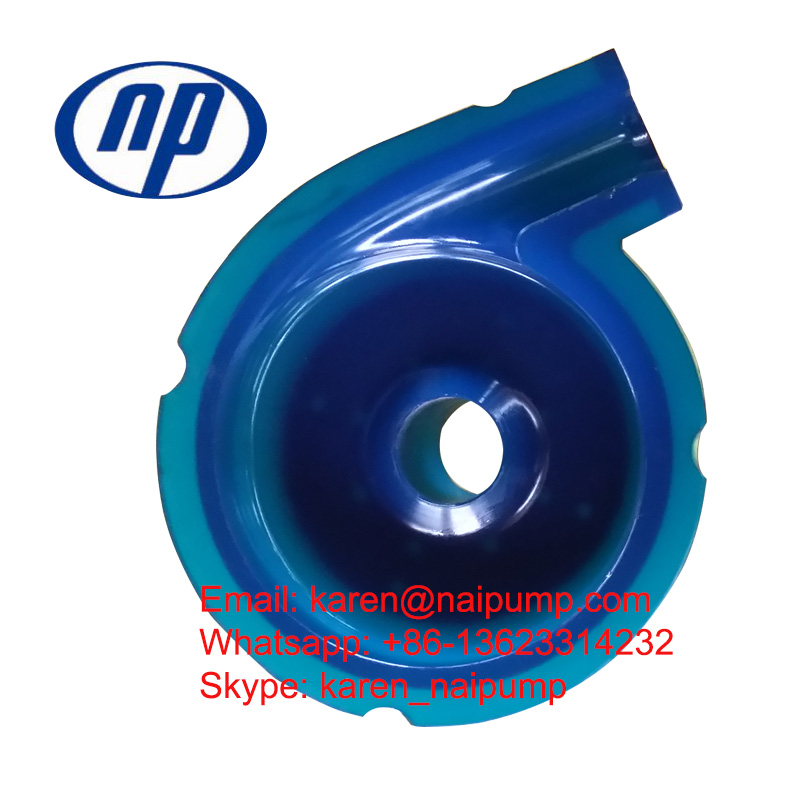

Polyurethane Pump Parts

Polyurethane (also named PU) is an unique material that has the elasticity of rubber combined with the toughness and durability of metal. It permits the engineer to replace rubber, plastic and metal with the ultimate in abrasion resistance and physical properties. Polyurethane can reduce plant maintenance.

Polyurethane slurry pump impeller (PUR and PU) is made by Polyurethane which is a polymer composed of a chain of organic units joined by urethane links. This impeller have better performance than natural rubber impeller for the slurry transportation.

Besides,we also have Polyurethane Cover Plate Liner,Frame Plate Liner,Throat Bush,Frame Plate Liner Insert etc.

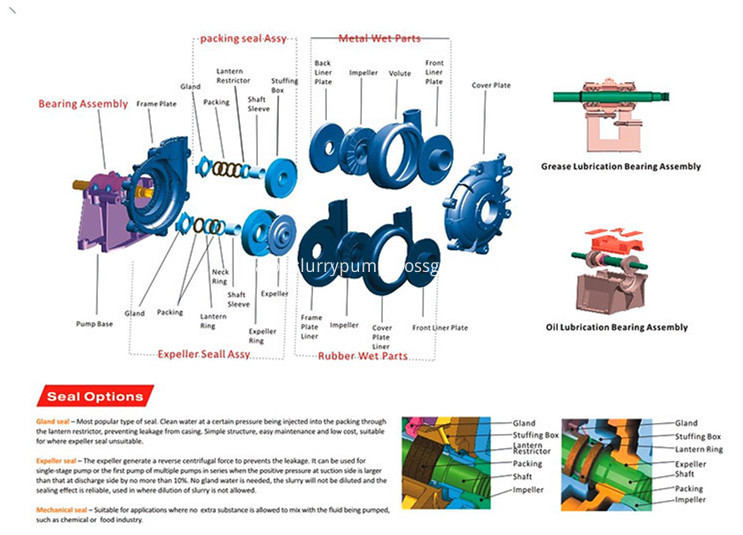

Construction Drawing:

Characteristics

The abrasion and tear resistance of Urethanes are much better than rubbers, while having higher load bearing capacity. Compared to plastics, urethanes have superior impact resistance, while having excellent wear properties and elastic memory. Besides, PU is more advance in weight reduction, noise abatement and wear resistance than metal parts.

However,Urethanes are unsuitable for temperatures exceeding 70ºC and for concentrated acids and alkalies,ketone,esters,chlorinated and nitro hydrocarbons.

Product Overview:

Polyurethane pump parts /PU parts/Polyurethane Parts/OEM Slurry Pump Parts /OEM Slurry Pump /OEM Impeller/ OEM High Chrome Alloy Pump Parts

Related other Products

Material Code

Part Name

001

E62

Adjusting Screw

003

G01

Base

005

Bearing Assembly

011

E62

Clamp Washer

013

D20

Cover Plate

015

E62

Cover Plate Bolt

017

R26A

Cover Plate Liner

018

R26A

Cover Plate Liner (Half)

024

E62

End Cover

028

G01

Expeller

029

G01

Expeller Ring

029R

R08A

Expeller Ring (Rubber)

032

D20

Frame Plate

034

E62

Frame Plate Bolt

036

R26A

Frame Plate Liner

039

E63

Frame Plate Stud

041

A05A,R26A

Frame Plate Liner Insert

043

R26A

Frame Plate Liner (Half)

044

K24

Gland Assembly

060

R08A

Intake Joint

062

D70

Labyrinth

063

K31

Lantern Ring

064

S18

Impeller O-Ring

067

E62

Neck Ring

070

E05

Shaft Key

073

E05

Shaft

075

D20

Shaft Sleeve

076

D20

Shaft Sleeve (Long)

078

G01

Stuffing Box

081

E02

Keeper Plate

083

A05A,R26A

Throat Bush

085

E02

Cotter

090

S10

Lip Seal

109

S18

Shaft O-Ring

110

A05A

Volute Liner

111

Q05

Packing

117

E62

Shaft Spacer

118

K31

Lantern Restrictor

118-1

K24

Lantern Restrictor(Low Flow)

122

R11A

Expeller Ring/Stuffing Box Seal

124

R08A

Volute Liner Seal

125

R08A

Volute Frame Seal

132

R08A

Discharge Joint Ring

138

E62

Grease Cup Adaptor

179

C23

Shaft Sleeve Spacer

210

S46

Shaft O-Ring

217

S18

Impeller O-Ring

239

C23

Impeller Release Collar

241

K24

Lip Seal Gland

302

E02

Lifting Tube

303

E02

Locating Nut

304

E02

Volute Lifting Beam

306

E02

Shaft Wrench

310

E02

Stuffing Box / Expeller Ring

425

R08A

Dyna Seal

430

U14

Nut Covers

005

Bearing Assembly

019

E02

Mounting Plate

041

A05A

Back Liner

064

S18

Impeller O-Ring

070

E05

Shaft Key

092

A05A

Casing

102

E02

Column

116-1

R10A

Strainer - Upper (Rubber)

116-2

G01

Strainer-Upper (Cast Iron)

116-3

U02A

Strainer-Upper(Urethane)

116-4

C23

Strainer-Upper(SS Mesh)

116L

U01A

Strainer-Lower

125

R08A

Back Liner Seal

154

E02

Discharge Pipe

204

R00

Discharge Pipe Gasket

231

E02

Suction Pipe

290

E02

Spacer

293

E02

Discharge Pipe Support

306

E02

Shaft Wrench

430

U04A

Nut Covers

005

Bearing Assembly

019

Mounting Plate

041

Back Liner

064

Impeller O Ring

070

Shaft Key

092

Casing

102

Column

116

Strainer-Upper

116L

Strainer-Lower

153

Column Clamp

154

Discharge Pipe

290

Spacer

291

Socket Head Protectors

293

Discharge Pipe Support

306

Shaft Wrench

421

U-Bolt

Material Code

Applications

Remark

SG01

Casing, Frame, Bearing housing, Stuffing box, Stuffing Gland

Grey Iron

SD21

Casing, Frame, Bearing housing

Spheroidal Graphite Cast Iron

SA05/SA33

Impeller, Volute, Expeller, Throat bushing, FPL, Expeller Ring

High Chrome Alloy

SA49

Impeller, Volute, Throat bushing, FPL

SR26/SR33/SR55

Impeller, Volute, Throat bushing, FPL

Rubber

OEM Material

Special material for pumps and pump parts are available according to clients chemical component request

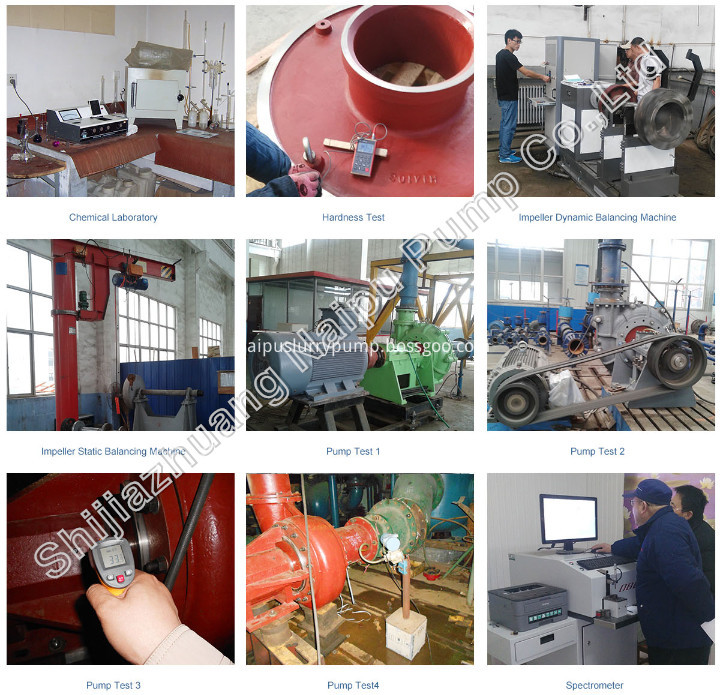

Quality Control System:

We set various check points along the whole production line,which throughout Raw Material,Charging Material,Surface and Heat Treatment checking,Material Analysis,Spare Testing and Pump Testing etc.

We set established a strict QA and QC system,we can provide quality control records such as "Spectrum Detection" "Metallographic Microscope Inspection" "Block Test" Ultrasonic Flaw Detection" "Penetration Testing " etc.And related test reports to our clients if necessary,such as "Material Test Report" "Dimensional Test Report" "Rotor Balancing Test Report" "NDT Test Report" "Hardness Inspection Report" etc.

Contact Details:

Shijiazhuang Naipu Pump Co.,Ltd

Add: No.368 Xinshi North Road,Shijiazhuang Hi-Tech Industry Development Zone,Hebei,China 050091.

Skype:karen_naipump

Contact Person:Karen Tan

If you have any queries,please feel free to contact us.

Related Keywords