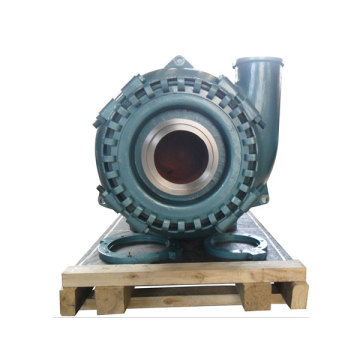

New Design Coal Mining Horizontal Slurry Pumps

-

$800.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air, Express, Express

- Port:

- Tianjin, Qingdao, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 200sets per month |

| Supply Ability: | 200Sets per month |

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,Express Delivery |

| Certificate: | ISO , CE |

| HS Code: | 8413709990 |

| Transportation: | Ocean,Land,Air,Express,Express |

| Port: | Tianjin,Qingdao,Guangzhou |

New Design Coal Mining Horizontal Slurry Pumps

Naipu is one of professional china factory of slurry pump ,sand gravel pump , dredging pump , and spare parts

Brief Introduction for Coal Mining Slurry Pump

Naipu® NP-ZG series Coal Mining Slurry pumps are cantilevered,horizontal,centrifugal slurry pumps. They are used international advanced solid-liquid two-phase flow theory and were designed using the Minimum-Wear Principle. The flow parts of this pumps are suitable for the flow of state media for it's set shape, which reduces hydraulic loss of eddy and impact, both in pump and along the pipeline; so reduced friction of flow parts, lower noise and vibration of the pump translates into improved hydraulic efficiency.

Typical Applications---

Electric Power

Constructional Material

Mine Coal

Coal washing

Sand Reclamation

Sugar Beet

Structural Features:

ZG series Coal Mining Slurry pumps product is a type of wearable and energy-efficient slurry pump, which uses the international advanced design theory and minimal loss principle design, to make the flow-parts shape and slurry flowing state to together achieve an ideal state.

MOC( Material of Composition) Features:

The flow-parts use high hardness alloy wear-resistant cast iron, which has high abrasion resistance, corrosion resistance and strong impact resistance, improved the service life. High-performance sealed, power voltage-reduction, slurry is not easy to leaking.

Drive Type:

It has direct coupled, belt, hydraulic, variable frequency speed regulation and other driving ways, it also can be operated in series connection or parallel connection according to users requirements.

Meanings of the model: 100ZJ-A50

ZJ----Product Series100----Press Out Diameter of 100mm

A----Number of Blades 5pcs

B----Number of Blades 4pcs

C----Number of Blades

50----Impeller Diameter of 500mm

NP-ZG Slurry Pump Construction Component

|

Main Part Number At The Drawing

|

1 Coupling

2 Shaft 3 Bearing Housing 4 Disassembly Ring 5 Expeller 6 Rear Liner Plate 7 Volute Casing 8 Impeller |

9 Front Liner Plate

10 Front Casing 11 Rear Casing 12 Stuffing Box 13 Water Seal 14 Base 15 Support |

Specifications for Coal Mining Slurry Pumps

|

Model |

Max.Power |

Clean WaterPerformance |

Max.Sizefor |

Weight |

||||

|

FlowRate Q(m3/h) |

PumpingHead |

RotateSpeedn |

Max.Efficiencyη(%) |

NetPositive |

||||

|

300ZJ-A100 |

450 |

464-1826 |

15.3-65.2 |

300-590 |

80.7 |

3 |

88 |

5265 |

|

300ZJ-A95 |

400 |

441-1735 |

13.8-58.8 |

300-590 |

77.7 |

3 |

88 |

5220 |

|

300ZJ-A90 |

560 |

505-1844 |

21.2-79.9 |

400-730 |

81.4 |

3.9 |

85 |

5005 |

|

300ZJ-I-A85 |

450 |

477-1742 |

18.9-71.3 |

400-730 |

78.4 |

3.8 |

85 |

4965 |

|

300ZJ-A70 |

630 |

635-2333 |

16.0-76.8 |

490-980 |

80.4 |

3.9 |

92 |

3560 |

|

300ZJ-A65 |

500 |

589-2166 |

13.8-66.2 |

490-980 |

77.4 |

3.7 |

92 |

3531 |

|

300ZJ-A56 |

250 |

395-1568 |

9.7-46.0 |

400-980 |

80.9 |

3.5 |

96 |

3030, |

|

250ZJ-A103 |

560 |

402-1573 |

29.7-110.5 |

400-730 |

74.5 |

2.8 |

69 |

5085 |

|

250ZJ-A96 |

560 |

403-1466 |

25.4-93.7 |

400-730 |

77.8 |

3.5 |

69 |

5035 |

|

250ZJ-A96 |

450 |

378-1374 |

22.3-82.4 |

400-730 |

73.8 |

3.4 |

69 |

4980 |

|

250ZJ-A85 |

800 |

376-1504 |

30.1-128.7 |

490-980 |

75.6 |

3.5 |

76 |

4530 |

|

250ZJ-A83 |

800 |

367-1469 |

28.7-122.7 |

490-980 |

74.6 |

3.5 |

76 |

4514 |

|

250ZJ-A80 |

710 |

354-1416 |

26.7-114.0 |

490-980 |

72.6 |

3.4 |

76 |

4490 |

|

250ZJ-A78 |

630 |

345-1380 |

25.4-108.4 |

490-980 |

70.6 |

3.2 |

76 |

4474 |

|

250ZJ-A75 |

560 |

300-1480 |

20.8-97.5 |

490-980 |

76 |

3 |

72 |

3480 |

|

250ZJ-A73 |

500 |

292-1441 |

19.7-92.4 |

490-980 |

75 |

3 |

72 |

3466 |

|

250ZJ-A70 |

450 |

280-1381 |

18.1-84.9 |

490-980 |

73 |

2.9 |

72 |

3446 |

|

250ZJ-A68 |

450 |

272-1342 |

17.1-80.1 |

490-980 |

72 |

2.7 |

72 |

3432 |

|

250ZJ-A65 |

315 |

299-1249 |

15.4-71.0 |

490-980 |

76.9 |

3 |

72 |

3020 |

|

250ZJ-A63 |

315 |

290-1211 |

14.4-66.7 |

490-980 |

75.9 |

3 |

72 |

3008 |

|

250ZJ-A60 |

280 |

276-1153 |

13.1-60.5 |

490-980 |

73.9 |

2.8 |

72 |

2991 |

|

250ZJ-A85 |

560 |

221-907 |

32.0-133.7 |

490-980 |

70.5 |

2.8 |

54 |

4110 |

|

200ZJ-A75 |

355 |

225-900 |

22.8-102.9 |

490-980 |

72.8 |

3 |

56 |

3070 |

|

250ZJ-A73 |

355 |

219-876 |

21.6-97.5 |

490-980 |

71.8 |

3 |

56 |

3056 |

|

250ZJ-A70 |

315 |

205-976 |

19.4-86.4 |

490-980 |

75.6 |

2.8 |

56 |

24, 65 |

|

250ZJ-A68 |

315 |

199-948 |

18.3-81.5 |

490-980 |

74.6 |

2.8 |

56 |

2453 |

|

250ZJ-A65 |

250 |

235-950 |

16.4-72.0 |

490-980 |

79.6 |

2.5 |

62 |

2323 |

|

250ZJ-A63 |

250 |

228-921 |

15.4-67.6 |

490-980 |

78.6 |

2.5 |

62 |

2311 |

|

250ZJ-A60 |

185 |

218-870 |

13.9-62.0 |

490-980 |

82.7 |

2.5 |

62 |

2223 |

|

250ZJ-A58 |

185 |

211-841 |

13.0-57.9 |

490-980 |

81.7 |

2.5 |

62 |

2214 |

|

150ZJ-A70 |

185 |

93-401 |

22.0-91.2 |

490-980 |

62.3 |

2 |

37 |

2245 |

|

150ZJ-A65 |

200 |

150-600 |

17.4-75.7 |

490-980 |

69.2 |

2.5 |

48 |

2223 |

|

150ZJ--A63 |

185 |

146-582 |

16.3-71.1 |

490-980 |

69.2 |

2.5 |

48 |

2211 |

|

150ZJ-A60 |

160 |

135-550 |

14.7-63.5 |

490-980 |

74.6 |

2.5 |

48 |

2203 |

|

150ZJ-A58 |

132 |

131-532 |

13.7-59.3 |

490-980 |

73.6 |

2.5 |

48 |

2033 |

|

150ZJ-A55 |

110 |

124-504 |

12.3-53.4 |

490-980 |

71.6 |

2.3 |

48 |

2019 |

|

150ZJ-C58 |

160 |

134-596 |

12.8-61.0 |

490-980 |

69.1 |

2 |

75 |

2063 |

|

150ZJ-A57 |

110 |

95-427 |

13.2-56.3 |

490-980 |

66.6 |

1.8 |

32 |

2023 |

|

150ZJ-A50 |

75 |

115-460 |

9.5-43.1 |

490-980 |

76.8 |

2.5 |

48 |

1735(1648) |

|

150ZJ-A48 |

75 |

111-442 |

8.7-39.7 |

490-980 |

75.8 |

2.5 |

48 |

1728(1641) |

|

150ZJ-C42 |

132 |

142-550 |

12.1-62.8 |

700-1480 |

76.4 |

2.2 |

69 |

1605(1518) |

|

100ZJ-A50 |

160 |

85-360 |

20.5-100.2 |

700-1480 |

68.5 |

2.5 |

34 |

1475(1388) |

|

100ZJ-A46 |

132 |

79-331 |

17.3-84.8 |

700-1480 |

66.5 |

2.3 |

34 |

1461(1374) |

|

100ZJ-A42 |

90 |

66-275 |

14.7-70.8 |

700-1480 |

70.4 |

2.5 |

35 |

1075(1021) |

|

100ZJ-A39 |

75 |

61-255 |

12.6-61.0 |

700-1480 |

68.4 |

2.4 |

35 |

1064(1010) |

|

100ZJ-B42 |

75 |

45-205 |

12.6-70.7 |

700-1480 |

63.2 |

1.8 |

18 |

1085(1031) |

|

100ZJ-A36 |

55 |

61-245 |

9.7-49.5 |

700-1480 |

71.6 |

2 |

32 |

1010(956) |

|

100ZJ-A33 |

45 |

56-225 |

8.2-41.6 |

700-1480 |

69.6 |

1.8 |

32 |

1003(949) |

|

80ZJ-A52 |

160 |

51-242 |

22.1-109.8 |

700-1480 |

56.3 |

2.1 |

21 |

1465(1378) |

|

80ZJ-A42 |

75 |

61-204 |

14.4-70.4 |

700-1480 |

66.7 |

2.5 |

24 |

1053(963) |

|

80ZJ-A36 |

45 |

46-190 |

9.6-51.4 |

700-1480 |

67.7 |

2.4 |

24 |

980(926) |

|

80ZJ-A33 |

37 |

43-174 |

8.0-43.2 |

700-1480 |

65.7 |

2.3 |

24 |

973(919) |

|

65ZJ-A30 |

15 |

23-79 |

7.4-34.8 |

700-1480 |

63.5 |

2 |

19 |

504(512) |

|

65ZJ-A27 |

11 |

20-71 |

6.0-28.2 |

700-1480 |

61.5 |

1.8 |

19 |

500(508) |

|

50ZJ-A50 |

90 |

27-111 |

22.3-110.7 |

700-1480 |

45.1 |

3 |

13 |

1378 |

|

50ZJ-A46 |

55 |

23-94 |

17.9-85.8 |

700-1480 |

44.7 |

1.4 |

13 |

1082(992) |

|

50ZJ-A33 |

18.5 |

12-54 |

7.7-42.5 |

700-1480 |

41.4 |

2.9 |

13 |

537(545) |

|

40ZJ-A17 |

4 |

4-23 |

9.0-44.6 |

1400-2900 |

52.4 |

2.5 |

11 |

121(127) |

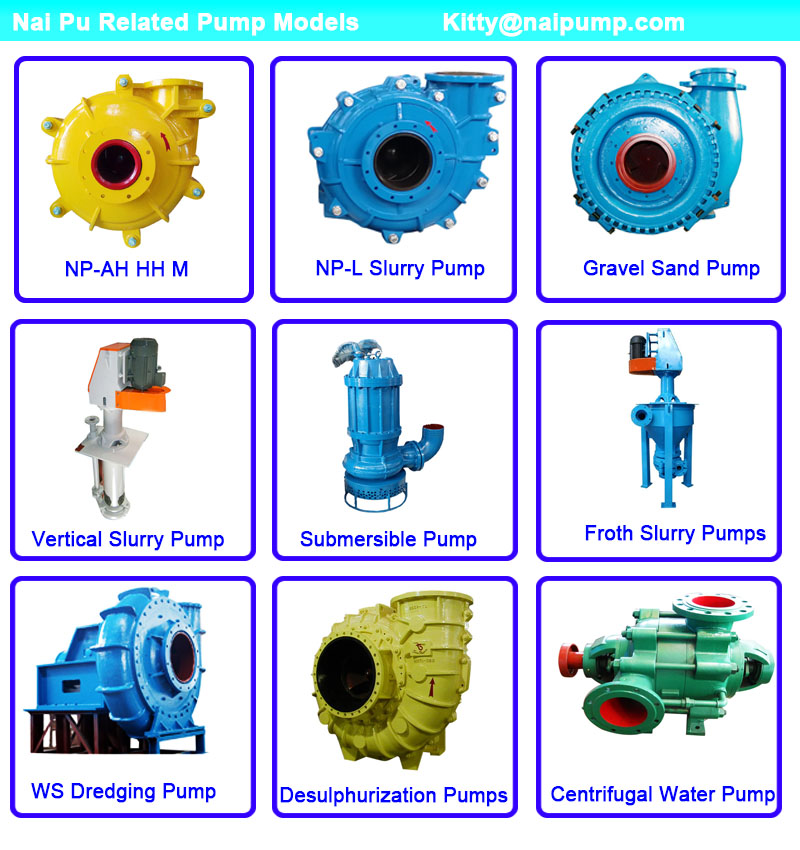

NAIPU Related Slurry Pumps

Welcome to contact me for more!

If you have any questions, please contactus directly.

Contact person : Kitty liu

Mail : kitty at naipump.com

Skype: kitty_naipump

WhatsApp:86-13032609126

Related Keywords