80-300 c purlin roll forming machine

- Payment Type:

- L/C, T/T, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land

- Port:

- Tianjin Xingang

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 600sets/year |

| Supply Ability: | 50sets/month |

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | CE/ISO |

| Transportation: | Ocean,Land |

| Port: | Tianjin Xingang |

80-300 c purlin roll forming machine

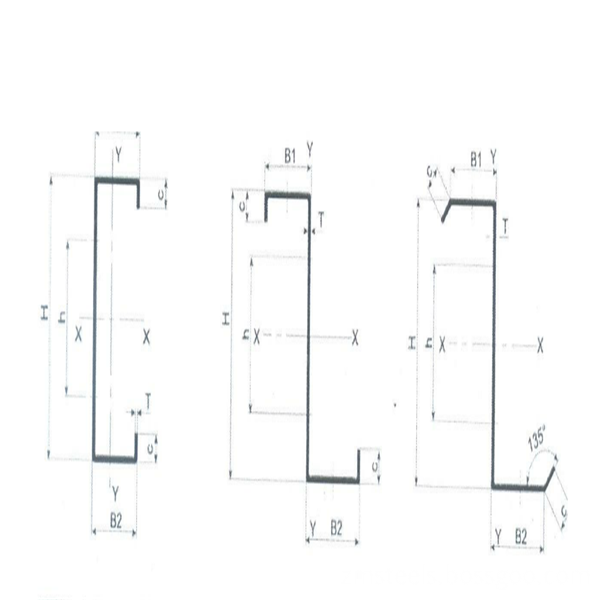

CZ Purlin Roll Forming Machine

The C/Z type steel machine equipment mainly consists of passive loading rack, leveling device, punching device, after forming cutting device, hydraulic station, computer control system and so on. This machine adopts automatic flying saw punching, easy to operate and so on.

C type steel finished rolling C/Z steel machine with bending and compression properties of good flatness good, automatic cutting, automatic punching, high degree of automation, convenient installation, can be used as the main products of large and medium-sized industrial and civil construction force structure, such as load bearing roof and wall flat workshop, warehouse and the garage, exhibition halls, theaters, stadiums, fair flower shed support. Cold bending steel is the main material for making light steel structure, which is made of steel plate or steel strip in cold bending.

The wall thickness of the C/Z steel machine can be made very thin C Steel Purlin, Galvanized Floor Roll Forming Machine, Custom Ridge Cap Roll Forming Machine, and it greatly simplifies the production process and improves the production efficiency. It is possible to produce cold-formed steel with uniform wall thickness but complex cross-section shape which is difficult to produce by general hot rolling method.

Specifications:

Thickness of material: 0.3mm-3mm

Main structure:400H steel

Wall plate: welded steel plate

Diameter of shaft: Ф80 solid

Chain: P=38.1

Electric motor power: 15KW

Reducer: 8# cycloid reducer

Roller: 18rows

Forming speed: 10-15m/min

Hydraulic Pressure: 16Mpa

Max width of coil can be loaded : 475 mmSteel Structure Building

Material of Rollers: Gcr15#

Cutting type: Hydraulic shearing

Motor: 380V, 50HZ/3 phase

Electrical part:CHINT,Delixi

Hydraulic motor: 5.5KW

Tail cutting material: Delta PLC-14ES

Size of machine: 8.2m*1.2m*1.2m

Warranty: 12 months limited warranty

Delivery: 30 days after receipt of advance payment

Package: Plastic packing and nude in the container

Payment Term: T/T, L/C, Trade assurance

Images

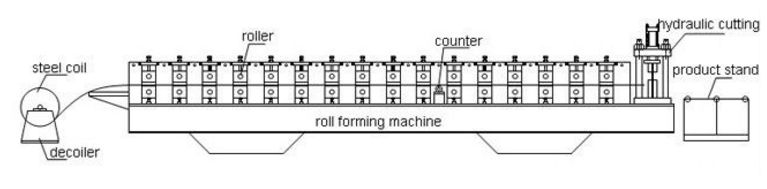

Working Flow

Technical specification:

Manual decoiler:weight capacity of decoiler : 5.0T

Feeding and Leveling Device:

It used for making the material flat before feeding into the roll forming machine, Galvanized Light Steel Stud Roll Forming Machine

Hydraulic Punching & Cutting (punching and cutting are before roll forming)

Punching Type: Hydraulic Punching

Cutting type: Hydraulic cutting

PLC Control System

Control the quantity &punching length& cutting length

PLC manufacturer: Japan Panasonic

Receive Table

Our products have been exported to Uganda, Bolivia, Russia, Slovenia, Turkmenistan...ect. Customers are all satisfied with our products and service.

OUR CUSTOMERS & OUR TEAM

Contact

Any interest in our roll forming machines, please contact with us at any time.

Related Keywords