2018 New Roof Tile Roll Forming Machine

- Payment Type:

- L/C, T/T, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean

- Port:

- Tianjin

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Hebei, China |

|---|---|

| Productivity: | 5 sets per month |

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO, SGS |

| HS Code: | 8455221000 |

| Transportation: | Ocean |

| Port: | Tianjin |

2018 New Roof Tile Roll Forming Machine

We can provide the classic panel drawings of roll forming machines for your choose,we also can make and design the kinds of roll forming machines according to your request. We have exported the 2018 new roof tile roll forming machine to Africa, South America, Russia, India, Pakistan,Southeast Asia etc. Custormers of domestic and foreign evaluate highly for our stable quality and cost effective. If you have any interest to our 2018 new roof tile roll forming machine, please contact with us. We will reply you at the first time.

Specifications:

Thickness of material: 0.2-0.8mm

Feeding width: 1000/1200mm

Effective width: 750/820/828/840/850/900/1050mm

Wall plate: 14mm

Diameter of shaft: Ф70-90

Hydraulic station power:3KW

Electric motor power: 3KW with Cycloidal reducer

Roller: 8-20 rows

Forming speed: 3-6m/min

Cutting type: Hydraulic shearing

Motor: 380V 3phase 50HZ or as the customer's requirements

The pro Images:

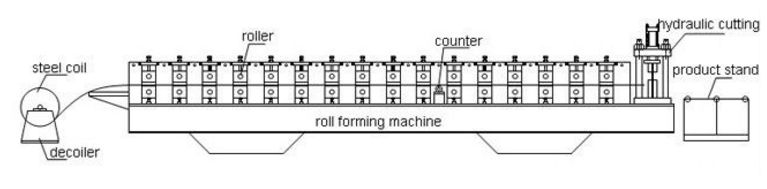

Produce process flow

Components

1. Cutting Mechanism

The Single Layer Roof Roll Forming Machine adopts hydraulic drive and automatic location to decide the dimention and cut the target products. Match equipment : one set of cutting tool, one hydraulic tank ,one cutter machine. Stop to cut , Post cut

2. Automatic Door Frame Cold Roll Forming Machine

M/C: Roller Mareial: 45# steel

3. Hydraulic systerm

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the Galvanized Roof Roll Forming Machine to begin the cutting job. Match equipment: a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes and two sets of electromagnetism valves.

It adopts Taida PLC to control(can make as your requirement). The target piece length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one.

5. Manual un-coiler

6. Recieving table

Main framework adopts welded steel and supported roller, and used for transmit and collect the finished products.

Packing&shippment

Related Keywords