two profile layer roll forming machine

- Payment Type:

- L/C, T/T, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land

- Port:

- Tianjin

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50sets/month |

| Supply Ability: | 50sets/month |

| Payment Type: | L/C,T/T,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Certificate: | CE/ISO |

| Transportation: | Ocean,Land |

| Port: | Tianjin |

two profile layer roll forming machine

Our copany can provide Double Layer Roll Forming Machine. And this Double Layler Steel Sheet Machine can produce Glazed Steel Roofing Tile and Galvanized Glazed Steel Roofing Tile at the same time. That means that this kind of machine can product two kinds profile drawing steel sheets at the same time. Of cource, the machine can not cut the two steel sheet at the same time, but compare with the single steel forming machine, it can save the space. if you are interested in our products, you can contact me.

Specifications:

Feeding material: PPGI steel coils

Thickness of the steel coils :0.3-0.8mm

Feeding width:1000/1200mm

Machine size: 6200mmX1700mmX1400mm

Diameter of the axle :down-Φ80mm/ up-Φ90mm

Rolling material: 45#

Rolling galvanization thickness:0.05 mm

Rolling stages:14-15 stages

Productivity:10-12m/min

Total power:5.5kw +3kw

Voltage:380V 60Hz 3phase or as requirement

Weight:about 4.5T

Base frame:350H steel

Side board thickness:16mm

Cutting blade: Cr12 with heat treatment

Cutting system: Hydraulic cutting system after forming

Control cabinet: PLC and frequency changer in it

Warranty:12 months limited warranty

Delivery: 30 days after receipt of advance payment

Package: Plastic packing and nude in the container

Payment Term: T/T, L/C, Trade assurance

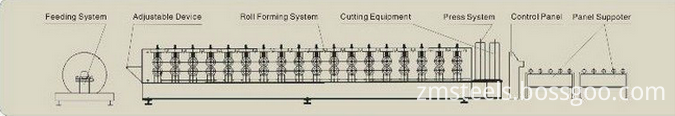

Production process flow:

It is mainly composed of feeding system, adjustable device, rool forming system, cutting equipent, press system and product output table.

Components:

1. Forming section:

Adjustable center of the forming rollers and of sufficient length to prevent lateral movement of the strip on its entry to flattener.

2. cutting:

cutting for forming: cut the sheet after roll forming to required length.

The cutting sequence is contained and controlled by the same PLC program.

material of blade: Cr12

cutting power by hydraulic: 4 KW

working pressure: 12MPa adjustable

3. automatic control system:

Automatic stopping of the equipment after completion of the cutting programme.

operating system language: English, Chinese, Russian.

The computer used to control length and quantity.

4. packing:

standard packing.

5. Contact

Related Keywords