30 45 galvanized double layer roll forming machine

- Payment Type:

- L/C, T/T, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land

- Port:

- Tianjin

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50sets/month |

| Supply Ability: | 50sets/month |

| Payment Type: | L/C,T/T,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Certificate: | CE/ISO |

| Transportation: | Ocean,Land |

| Port: | Tianjin |

two profile layer roll forming machine

Our company can provide Double Layer Roof Roll Forming Machine with high quality and competitive price. This product can be used to manufact Steel sheet . And it can provide two kind profiles shees at the same time. What is more, our company owns more than ten years experience, adviced machines and trained workers. Our aim is to provide you best service. If you are interested in our products, you can contact me.

Product Specificition

Main frame 300/350/400mm H beam steel

Voltage 380V/60HZ/3PH

Sideboard 14mm-16mm

Motor Power 3-6KW

Hydraulic Power 3-6KW

Up layer rollers 12-20 rows of rollers

Down layer rollers 12-20 rows of rollers

Roller material 45#steel

on the surface of rollers, polished all the rollers

Shafts materials 45# steel

Shafts diameter 70mm to 90mm

PLC control system Delta or Siemens

Screen TouchWin

Cutting blade Cr12

Cutting type Hydraulic cutting

Tolerance ±1mm

Working Speed 8 -12m/min

Effective Cover Width 750-1250mm

Feeding Material Width 1000mm-1500mm

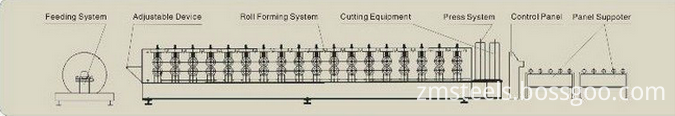

Production process flow:

It is mainly composed of feeding system, adjustable device, rool forming system, cutting equipent, press system and product output table.

Components:

1. Forming section:

Adjustable center of the forming rollers and of sufficient length to prevent lateral movement of the strip on its entry to flattener.

2. cutting:

cutting for forming: cut the sheet after roll forming to required length.

The cutting sequence is contained and controlled by the same PLC program.

material of blade: Cr12

cutting power by hydraulic: 4 KW

working pressure: 12MPa adjustable

3. automatic control system:

Automatic stopping of the equipment after completion of the cutting programme.

operating system language: English, Chinese, Russian.

The computer used to control length and quantity.

4. packing:

standard packing.

5. Contact

Related Keywords