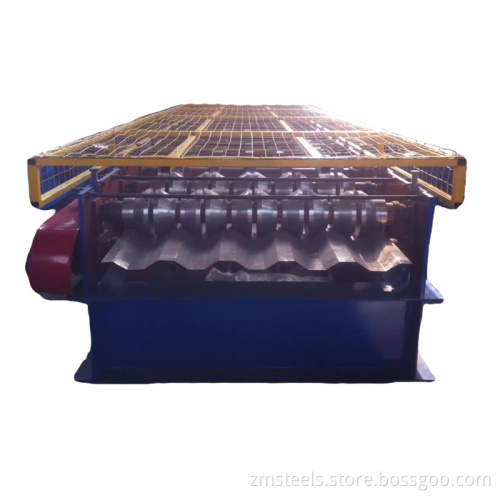

zinc roofing sheet roll forming construction machine

- Payment Type:

- L/C, T/T, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land

- Port:

- Tianjin Xingang

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 600sets/year |

| Supply Ability: | 50sets/month |

| Payment Type: | L/C,T/T,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | CE/ISO |

| Transportation: | Ocean,Land |

| Port: | Tianjin Xingang |

zinc roofing sheet roll forming construction machine

We are chinese company with our own factory. Our factory has advanced machines, many-year experience, trained workers. And our aim is providing you the best service. Glazed Tile Toof Roll Forming Machine is one of our main products. It can be used to be manufactoring Glazed Steel Roofing Tile. Apart of it, we can provide Corrugated Steel Sheet, Trapezoidal Rib Steel Roof Tile, Rock Wool Sandwich Panels and so on. If you are interested in our products, you can contact me.

Specifications:

Components Parameter

Main Frame 300/350/400mm H beam steel

SideBoard 14mm-16mm

Decoiler Manual decoiler or Hydraulic decoiler (optional)

Forming speed 8-15m/min

Rollers 8-20rows of rolles(customizable)

Shafts diameter 70mm to 90mm

Roller materials 45#steel

Transmission By chain(1.0 inch), link bearing model 6210

Main motor power 3-6kw(customizable)

Cutter material Cr12

Cutter stype Hydraulic cutting

Hydraulic power 3kw to 6kw(customizable)

Length cut Accuracy ±1mm

PLC control system Delta or Siemens

Voltage 380V/50HZ/3Phase(customizable)

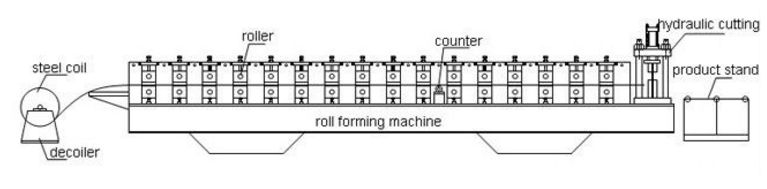

Produce process flow

Components

1.Manual un-coiler:to load steel coils

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job. Match equipment: a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes and two sets of electromagnetism valves.

It adopts Taida PLC to control(can make as your requirement). The target piece length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one.

5. Cutting Mechanism

It adopts hydraulic drive and automatic location to decide the dimention and cut the target products. Match equipment : one set of cutting tool, one hydraulic tank ,one cutter machine. Stop to cut , Post cut

6. Recieving table:Main framework adopts welded steel and supported roller, and used for transmit and collect the finished products.

Packing&shippment

1.Packing:the main parts will be packed with plastic film then fixed to container by iron wire

2.Shippin:shipped in 30days after receiving the full deposit

Related Keywords