fully automatic steel roof truss making machinery

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- Tianjin, Qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50sets/month |

| Supply Ability: | 600sets/year |

| Transportation: | Ocean |

| Port: | Tianjin,Qingdao |

full automatic galvanized corrugated roofing steel machinery

Other profiles machine

Glazed roll forming machine &Double Layer Roof Roll Forming Machine

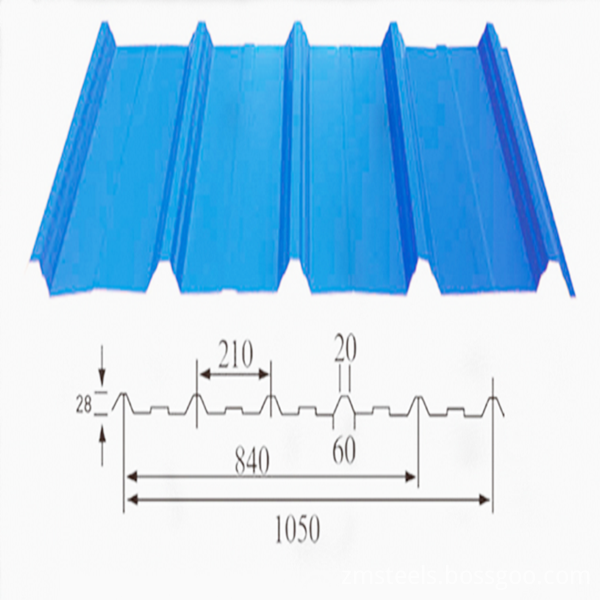

1. Technique parameters of the processing line

Model No.:Roll Forming Machines

Main moter power:3KW

Hydraulic station power:3KW

Hydraulic oil pump:CB-E310

Shearing die:Gr12

Sprocket:P-25.4(1 inch)

Transmission mode:chain

The bearing capacity of manual decoiler:5 Tons

Roller station:11rows

Main frame structure:250 H steel

Diameter of principal axis:70mm

Material of roller:45#steel hard chrome/Hardness HR55°-57°/Solid shaft

Processing speed:12 m/min

Material: Galvanized Steel Coil/ Prepainted Galvanized Steel Coil/ Galvalume steel coil

Steel Coil width: 1000/1200MM

Steel Coil Thickness:0.2-0.7mm

Appliance:Roofing sheet,wall sheet

Installation dimension about(L*W*H):6300mm*1300mm*1300mm

Total weight:About 3 Ton

Delivery time:25days

2. Components of line:

1-Decoiler-1set

2-Main machine for roll forming-1set

3-Control system-1set

4-Hydraulic system-1set

5-Post cut-1set

6-Output table-1set

3. Technical Specification

(1) Manual decoiler

Un-powered; single head;

Max.capacity for steel coil: 5000kg

(2) Roll-Forming M/C:

Steps:12-13 Roller Material: 45# steel

Voltage:380V/220V 50HZ 3P line speed: 8-12m/min

(3) Cutting Mechanism

It adopts hydraulic drive and automatic location to decide the dimension

and cut the target products.

Match equipment : one set of cutting tool, one hydraulic tank ,one

cutter machine.

No stop to cut .Cutting tool material: GCr12

(4) Hydraulic System

It is controlled by gear wheel oil pump. After filling the hydraulic oil

into the hydraulic oil tank, the pump drive

the cutter machine to begin the cutting job.

Match equipment: a set of hydraulic tank , a set of hydraulic oil pump,

two hydraulic pipes and two sets of electromagnetism valves.

Power of the oil pump:3kw Hydraulic oil :46#

(5)Computer control cabinet :

It adopts Panasonic PLC to control. The target piece length is adjustable

and digit of it can be adjusted.

Computed mode has two modes: automatic and manual one.

(7) Counter :

One counter gauges length, pulses, and decides length

(8) Output table

It used to load the forming plate

(9)Spare parts

Oil pipe,magnetic valve,spacer

5. Packing method

Packing: nude, with waterproof cloth and stow-wood. The computer

controlled cabinet is packed with

waterproof cloth and box. The seller should guarantee equipments will

be moisture-proof, anticorrosive,

and will not be damaged during transportation.

6. Delivery Time

The Seller guarantees the equipment will be ready for shipment within

25 working days after receipt of deposit from the Buyer.

7. one complete equipment need one 20 feet container to hold

8. Packing: NAKED

9.Orders & Payment Term

30% of the total contract value paid by T/T as deposit, the rest 70% of the

total contract value to be paid

by T/T after inspection by buyer in seller`s factory while before delivery.

10. Guarantee:

In correct operation and maintenance, the machine is one year guarantee

since leaving the seller`s factory.

11. Installation:

If buyer need, the seller will send one or two technician to the buyer`s

factory to install & testing the machine,

the buyer will assist the seller`s technician to get the visa and pay for

the two-way flight tickets and local accommodation, visa cost. by the way ,

buyer pay 100USD/day for technican extra.

12. Contact me:

Related Keywords