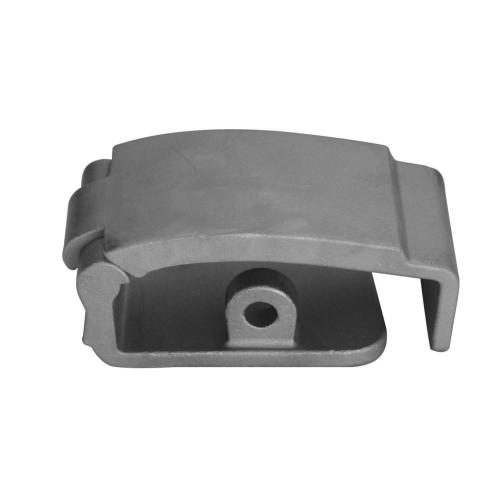

OEM/ODM Custom Stainless Steel Casting Part

-

USD10≥100 Kilogram

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA, CPT

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Delivery Time:

- 20 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Tianjin

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10 Ton/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin |

We are very experienced in stainless steel casting. With strong capability of casting a wide variety of stainless steel alloy, we provide custom stainless steel casting parts and components for industries and applications including automotive, food & dairy, machinery, medical, plumbing, watering, mining, petrochemical, electrical, energy, aerospace, submarine and others. We can assure you high quality stainless steel castings. The sizes of the stainless steel casting parts range from 0.1 inch up to 24 inches. The weights of the stainless steel casting parts are from an ounce to 50 pounds. Typical tolerances are ± .005" per inch.

What Is Investment Casting?

Investment casting refers to the formation of ceramics around a wax pattern to form a shell for casting molten metal. Once wax patterns are created, they are melted into the gate system, immersed in slurry and sand to form a layered shell, and then replaced by molten metal such as stainless steel, aluminum, or the like.

How are Investment Castings Made?

Investment casting involves creating an original wax model, building the image with plaster and successive layers until a strong shell surrounds the model. After melting the wax, pour the molten gold or bronze into the mold to create a perfect replica of the original wax pattern. Investment casting provides economical undercutting, high resolution, sophisticated detail and smooth surface finish compared to machining separations. In most cases, investment casting is the only way the part can be made economically.

Linear Tolerance of Investment Casting

Normal linear tolerances of investment casting are as follows as a general rule: Up to 1" +/- .010", for each additional inch up to ten inches +/- .003" per inch. For dimensions greater than ten inches allow +/- .005" per inch. Secondary operations such as straightening and sizing will produce closer dimensional tolerance.

Advantages of Investment Casting

- Sizes: 0.1 in to more than 3 feet

- Weights: a few grams to one metric ton

- Surface: very smooth finish

- Tight tolerances

- Reliable process controls and repeatability

- Design and casting versatility

- Efficient production

- Affordable tooling

- Material variety

Our factory

Related Keywords