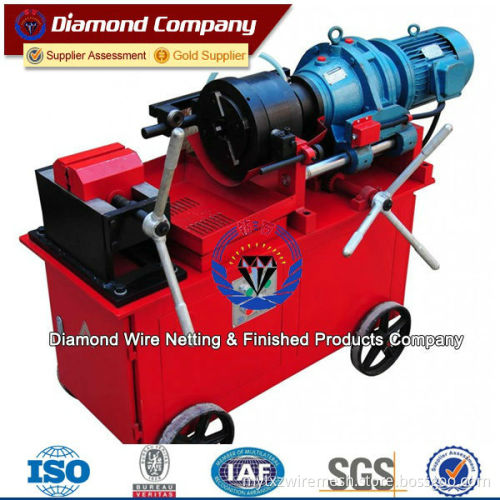

hydraulic flat die automatic thread rolling small machine

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Hebei, China (Mainland) |

|---|

Rebar tapered threading machine is use for Cutting External Thread on Rebar by Chasing method. HSS Rebar Threading Tangential Chasers are use as cutter. Rebar remains stationery and Die Head rotates. Matric, BSP, BSPT, NPT, UNF,UNC, BSW, Acme Threads B.S.F etc. threads can be cut on this rebar threading machine depending upon the type of Rebar Threading Chasers. The Rebar tapered threading machine mainly consists the following:

* Base

* Head Stock

* Saddle

* Bed or Pillar Type Clamping Vice

* Die Head

1.Main Techincial Parameter:

1.Voltage:3-380V 60Hz

2.Motor Power:4.0KW

3.The Max Thread Length:200mm/300mm(Customized by customers request)

4.Spindle Speed:40-62R.P.M

5.Thread Angle:55/60/75 degree

2.Specification:

Model |

GSJ-40-90 |

|

Rebar thread rolling machine head model |

40model |

|

Rolling wheel model |

HA25-1 |

HA30-1 |

Pitch |

2.5 |

3.0 |

Specification of rebar |

16 18 20 22 |

25 28 32 |

Weight |

315kg |

|

Motor power |

4KW |

|

Water pump motor power |

10W |

|

Voltage |

380V 50Hz |

|

Size |

1150X640X1090mm |

|

3.Features:

1 Machine adopts low-pressure control system, simple operation, safe and reliable.

2 The screw pitch angle mechanism in machine rolling head saves time and energy when processing thread.

3 Use one machine head to make left thread and right thread. When processing left thread, rib stripping and thread rolling can be continuously completed with one time start-up.

4 The rib-stripping plate adopts the latest patent technology can adjust position freely, it helps double the rib-stripping plate’s lifespan.

5 Slightly adjust the machine rolling head, the thread processing length could reach 100mm.

6 Equipped with four adjusting supporting bolsters to facilitate the machine leveling.

7 Equipped with four rings to make it easy to move the machine.

8 High processing speed and production efficiency, energy conservation and environmental protection.

4.Application:

1. Cutting off the end of the rebar

2. Peeling the ribs off the end of the rebar and then rolling thread directly.

3. Splice the rebar by using the coupler.

5.About our products:

6.ISO Certification

7.About Diamond

8.Contact us:

Related Keywords