SMAH50-C Heavy Duty Slurry Pump

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean

- Port:

- Tianjin in China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shijizhuang |

|---|---|

| Supply Ability: | 20/month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Transportation: | Ocean |

| Port: | Tianjin in China |

SMAH50-C Heavy Duty Slurry Pump

Product Profile

SMAH50-C heavy duty slurry pump has high interchangeability with Warman pump 3/2C-AH, whose outlet diameter is 2 inches and inlet diameter is 3 inches, which can withstand the extreme wear from coarse, heavy solids and flow turbulence, performing under even the most aggressive workloads. This one type of AH(R) series tailing thickener slurry pumps built from high chrome cast iron is ideal for transporting large particle slurries.

The 2 inches mineral processing pump is designed for heavy duty applications such as mining and mineral processing, mill discharge, sand and gravel, slurry transfer, cyclone feed, boost pumps as well as other specialty applications.

Performance parameter:

Flow: Q=39.6~86.4 m3/h

Head: H=12-64 m

Speed: n=1300-2700 r/min

Weight: 191 Kg

Allowable Mating Maximum Power: 30Kw

Model Meaning:

For example: SMAH(R)25-B (AH: Metal Horizontal Centrifugal Slurry Pump; AHR: Rubber Horizontal Centrifugal Slurry Pump;25: Discharge Diameter(mm) ;B: Frame Type.)

Product Feature

1. High performance materials with excellent resistance to abrasion, corrosion and erosion.

2. Excellent interchangeability of metal and rubber parts.

3. The discharge position by request may be rotated 8 different angles at intervals of 45 degrees.

4. Various shaft seal options including gland seal, expeller drive seal and mechanical seal.

5. High capacity bearing design.

6. Application at best efficiency point and selection of wear-resistant material give long life.Construction Description

1 Suction Seal 2 Cover Plate 3 Impeller 4 Stuffing Box 5 Shaft Sleeve 6 Frame 7 Bearing Assembly 8 Packing 9 Front Lantern Ring 10 Rear liner 11 Frame plate 12 Liner 13 Discharge Seal

Other shaft sealing structures

(1) Expeller Seal Structrue

1 Packing

2 Metal Release Gland

3 Oil Cup

4 Packing Gland

5 Lantern Ring

6 Packing Gasket

7 Expeller

(2) Mechanical Seal Structure

1 Mechanical Seal Box

2 Stationary Ring Assembly

3 Movable Ring Assembly

Performance Curves

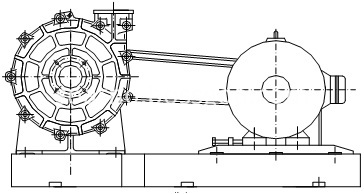

DCz Drive CV Drive

CRz Drive ZVz Drive

Competitive Advantage

1. Factory price, top quality.

2. Has many successful projects.

3. Professional pumps manufacturing and service experience.

4. Skilled team to provide you specialized technical support.

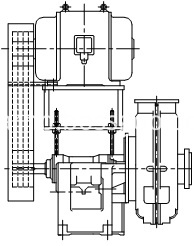

Outline Drawing

Related Keywords