400mm Double Suction Centrifugal Water Pump

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30-60 Days

- Transportation:

- Ocean

- Port:

- Tianjin In China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shijiazhuang |

|---|---|

| Supply Ability: | 10 Set/Month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Transportation: | Ocean |

| Port: | Tianjin In China |

HDSN400 Double-suction Split Case Centrifugal Pump

• Product Introduction

HDSN400 centrifugal split case pump is one of HDSN series double suction pump and its suction diameter is 400mm. This pump is a single-stage centrifugal horizontal split pump. The pump is large and has large flow capacity. The greatest feature of this pump is: wide-range performance, high efficiency, compact construction, reliable operation, easy maintenance and long service life. This pump impeller has M and N two types and different diameter to meet different performance.

This product is often used as a water intake pump or circulating pump widely applicable to tap water, irrigation, pump station system, power station circulating water system, industrial water supply system, fire protection system, Marine industry and petrochemical industry and other fields.

• Product Feature

1.Wide range of performance: According

to the required performance points, the prototype impeller (M type), the

modified impeller (N type) and its cutting impeller can be used.

2. Excellent

absorptive capacity:This series of double

suction pumps have excellent absorption capacity, excellent cavitation

performance and can operate at high speed.

3.Diversity of material:In addition to the standard materials, this

series of pumps are made of various materials suitable for different media.

Including gray iron, ductile iron, cast steel, stainless steel and other

materials.

4.Smooth operation, low vibration, low noise:The impeller adopts double suction structure,

and the pump body adopts double worm shell structure. The axial force is

reduced to the minimum, and the distance between bearings is shortened as far

as possible, so as to reduce vibration and noise.

5.Easy maintenance:This axially split pump provides convenience for

the maintenance of the rotor part (including bearing, sealing and other

vulnerable parts). It can be operated by simply opening the pump cover, without

disconnecting the inlet and outlet pipelines, couplings and even motors.

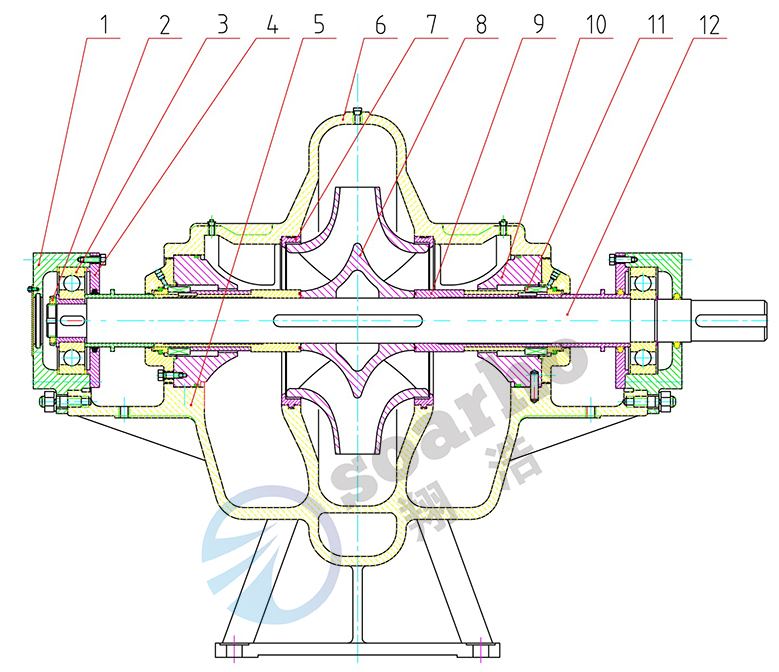

1 Bearing body 2 Rround nut 3 Bearing 4 Bearing cover

5 Pump casing 6 Pump cover 7 Sealing ring 8 Impeller

9 Shaft sleeve 10 Sealing body 11 Sealing component 12 Shaft

• Performance List

Type

Impel. Dia.

(mm)

Capacity

Head

(m)

Speed

r/min

Power(KW)

Eff.

(%)

NPSHr

(m)

Pump

weight

(kg)

(m3/h)

(L/s)

Shaft power

Motor power

HDSN400

-M160

725

1211

2018

2523

336.3

560.6

700.7

180

160

151

1480

760.9

1034.5

1234.9

1250

78

85

84

5.0

1954

675

1151

1918

2398

319.7

523.8

666.0

157

137

120

1480

630.8

841.9

944.0

1000

78

85

83

4.9

1950

620

1019

1818

2273

303.0

505.0

631.3

130

111

97

1480

495.1

654.2

732.1

800

78

84

82

4.8

1946

570

1025

1708

2135

284.7

474.4

593.1

108

91

76

1480

391.4

503.9

566.5

630

77

84

78

4.7

1943

HDSN400

-N160

724

1079

1798

2248

299.7

499.4

624.3

176

150

134

1480

662.9

874.4

1012.6

1120

78

84

81

4.8

1952

674

983

1638

2048

273.0

455.0

568.8

146

125

108

1480

514.2

671.8

743.5

800

76

83

81

4.7

1948

619

929

1548

1935

258.0

430.0

537.5

123

105

89

1480

409.4

533.3

579.0

630

76

83

81

4.6

1944

570

875

1458

1823

243.0

405.0

506.3

98

81

68

1480

315.5

392.2

421.9

450

74

82

80

4.5

1941

HDSN400

-M94

573

1211

2018

2523

336.3

560.6

700.7

107

94

81

1480

446.6

600.7

670.4

710

79

86

83

6.0

1730

526

1123

1872

2340

312.0

520.0

650.0

89

77

66

1480

349.0

461.8

506.7

560

78

85

83

5.9

1728

486

1075

1792

2240

298.7

497.8

622.2

74

63

53

1480

281.4

361.7

394.3

400

77

85

82

5.8

1725

446

1045

1742

2125

290.3

483.9

590.3

62

51

41

1480

238.5

291.5

308.2

315

74

83

77

5.7

1723

HDSN400

-N94

585

1110

1850

2313

308.3

513.9

642.4

112

92

74

1480

434.1

545.3

582.5

630

78

85

80

5.9

1730

573

1039

1732

2165

288.7

481.1

601.4

96

80

67

1480

348.3

443.9

481.7

500

78

85

82

5.8

1728

526

943

1572

1965

262.0

436.7

545.8

82

68

58

1480

277.1

342.5

378.5

400

76

85

82

5.7

1726

486

901

1502

1878

250.3

417.2

521.5

70

59

49

1480

235.3

290.8

309.3

315

73

83

81

5.6

1724

HDSN400

-M59

481

1215

2025

2520

337.5

562.5

700.0

71

59

51

1480

313.2

374.0

416.7

450

75

87

84

7.3

1652

470

1211

2018

2502

336.3

560.6

695.1

65

52

43

1480

282.0

324.7

344.7

355

76

88

85

7.2

1650

438

1148

1914

2393

319.0

531.7

664.6

57

45

37

1480

240.9

272.7

290.5

315

74

86

83

7.1

1647

406

1082

1804

2255

300.7

501.1

626.4

47

37

27

1480

189.8

216.4

215.3

250

73

84

77

7.0

1642

374

1016

1694

2118

282.3

470.6

588.2

38

28

20

1480

146.1

161.5

155.9

185

72

80

74

6.9

1640

HDSN400

-N59

481

1047

1745

2181

290.8

484.7

605.9

68

57

47

1480

255.1

311.3

340.5

355

76

87

82

7.0

1650

470

1039

1732

2165

288.7

481.1

601.4

63

52

41

1480

231.6

277.6

284.4

315

77

88

85

7.0

1648

438

979

1632

2040

272.0

453.3

566.7

56

45

34

1480

199.1

229.9

233.2

250

75

87

81

6.9

1646

406

922

1537

1921

256.2

426.9

533.7

48

38

29

1480

165.1

189.4

189.7

200

73

84

80

6.8

1641

374

859

1432

1790

238.7

397.8

497.2

39

31

23

1480

125.0

151.1

147.5

185

73

80

76

6.7

1639

HDSN400

-M32

402

1211

2018

2523

336.3

560.6

700.7

43

32

24

1480

194.2

202.1

208.7

220

73

87

79

8.5

1195

377

1181

1968

2460

328.0

546.7

683.3

37

27

19

1480

163.0

170.2

163.2

185

73

85

78

8.4

1193

352

1151

1918

2398

319.7

532.8

666.0

31

22

13

1480

134.9

138.4

108.8

160

72

83

78

8.3

1191

337

1121

1868

2335

311.3

518.9

648.6

25

16

8

1480

107.5

101.7

69.7

110

71

80

73

8.2

1191

HDSN400

-N32

402

1039

1732

2165

288.7

481.1

601.4

39

31

24

1480

149.2

170.0

170.5

185

74

86

83

8.0

1194

377

985

1642

2053

273.7

456.1

570.1

34

27

20

1480

125.0

143.7

141.5

160

73

84

79

7.9

1192

352

943

1572

1965

262.0

436.7

545.8

29

23

16

1480

103.5

120.1

109.8

132

72

82

78

7.8

1190

337

901

1502

1878

250.3

417.2

521.5

25

18

12

1480

86.4

94.4

82.9

110

71

78

74

7.7

1189

Related Keywords