16/14TU-GH High Head Gravel Pump

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean

- Port:

- Tianjin In China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shijiazhuang |

|---|---|

| Supply Ability: | 20 Set/Month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Transportation: | Ocean |

| Port: | Tianjin In China |

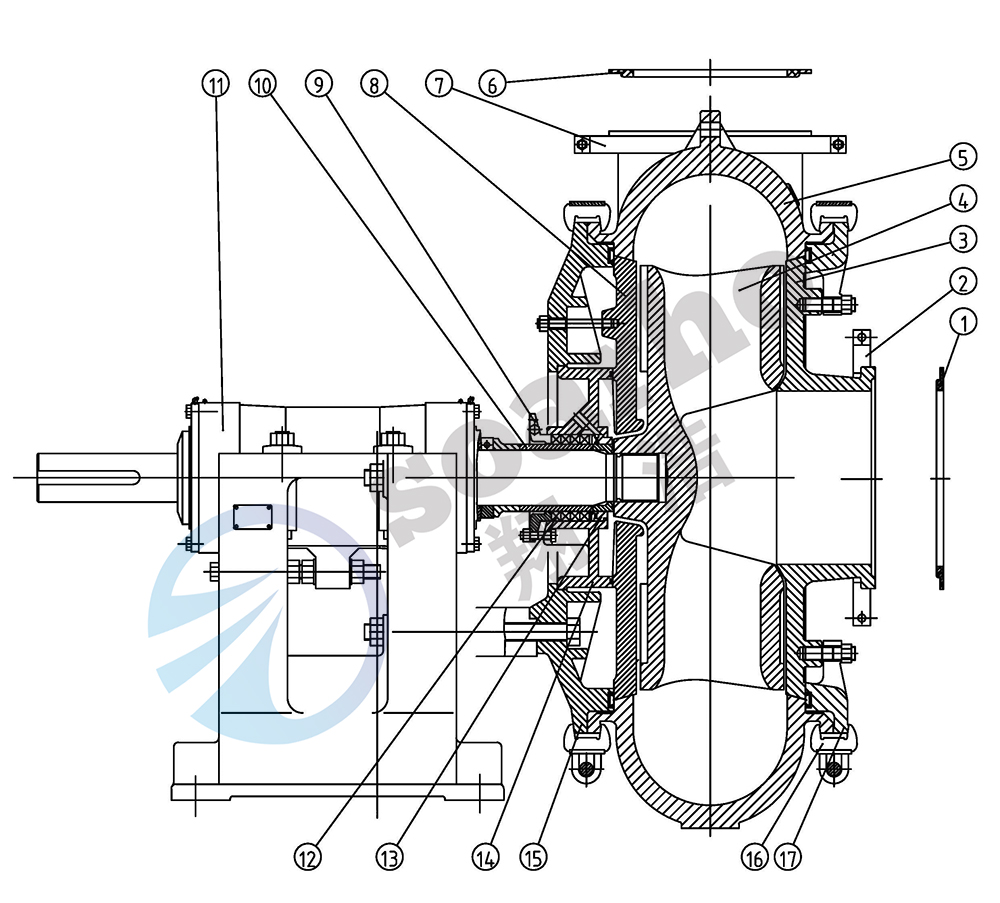

16/14TU-GH High Head Gravel Pump

• Product Introduction

16/14TU-GH is 14inches high head gravel horizontal slurry pump.It is .The wide flow channel is suitable for large size slurry passing.The single shell connected with cassette,so that the discharge direction could be positioned at any angle to fit different site installation condition.This gravel sand pump belongs to GH series high head sand suction pumps,it is characterized by excellent abrasion resistance, corrosion resistance, high reliability, reasonable structure, reliable operation and long service life etc.This pump is suitable for continuously delivery of mediums with strong abrasion the particle of which is too large for common slurry pump to transfer. It is mainly applied to dredger, river training, mining and delivery of metal smelting slag etc. and it is particularly suitable for shield system,can be used as high head shield machine pump.

• Product Feature

1. Single casing structure connected with cassette, wide passage, hard alloy liner with excellent wear resistance, corrosion resistance, good reliability and good cavitation performance.

2. The bearing assembly is cylinder type structure , the bearing could be lubricated by grease or oil to fit different site condition.

3. The clearance between the impeller and the cover plate could be adjusted to ensure the pump to operate at high efficiency point.

4. Packing seal, expeller seal and cartridge mechanical seal could be selected as shaft seal to fit different site condition.

5. Pump and drive machine can choose direct drive, v-belt drive, hydraulic coupling drive, reducer drive.

6. The discharge direction could be positioned at any angle to fit different site installation condition.

1 Suction seal

2 Suction split flange

3 Front liner

4 Impeller

5 Frame plate

6 Discharge seal

7 Discharge split flange

8 Rear liner

9 Packing gland

10 Shaft sleeve

11 Bearing assembly

12 Packing

13 Front water seal ring

14 Packing box

15 Join plate

16 Cassette

17 Cover plate

• Range of Performance

Capacity 324-3600m3/h

Head 26-70m

Discharge diameter: 350mm

• Outline Drawing

Related Keywords