150SVL-SP Lengthening Sump Slurry Pump

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean

- Port:

- Tianjin In China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shijiazhuang |

|---|---|

| Supply Ability: | 20 Set/Month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Transportation: | Ocean |

| Port: | Tianjin In China |

150SVL-SP Lengthening Sump Slurry Pump

• Product Introduction

150SVL-SP belongs to SP sump slurry pump,which is widely applied to sewage treatment ,metallurgy, mining, coal, power plant, building materials industries and so on.

150SVL-SP is suitable for the condition of deep liquid level.The pump is long shaft sump slurry pump.It is vertical, centrifugal slurry pump submerged in water to work. The pump It is designed for delivering abrasive, large particle and high-density slurries. The pump needn't shaft sealing or sealing water.It is able to operate normally under condition of insufficient suction volume. Wet parts of this type pump are composed of abrasion -resistant and corrosion-resistant high chrome cast iron parts.

• Product Feature

- Vertical, centrifugal and Single casing sump slurry pump.

- The Impeller is double suction half-open structure, adopts wear-resistant alloy or rubber.

- The bearing assembly is cylinder type structure, the bearing could be lubricated by grease.

- The clearance between the impeller and the cover plate could be adjusted to ensure the pump to operate at high efficiency point.

- Needn't shaft sealing or sealing water.

- Direct drive, V-belt drive could be selected to connect with the drive.

- The lengthened shaft series of sump pump can be applied to the condition of deep liquid level. This kind of pump has added guide bearing structure on the basis of standard pump, which makes the operation more stable and applies more widely. However, the bearing should be equipped with flush water.

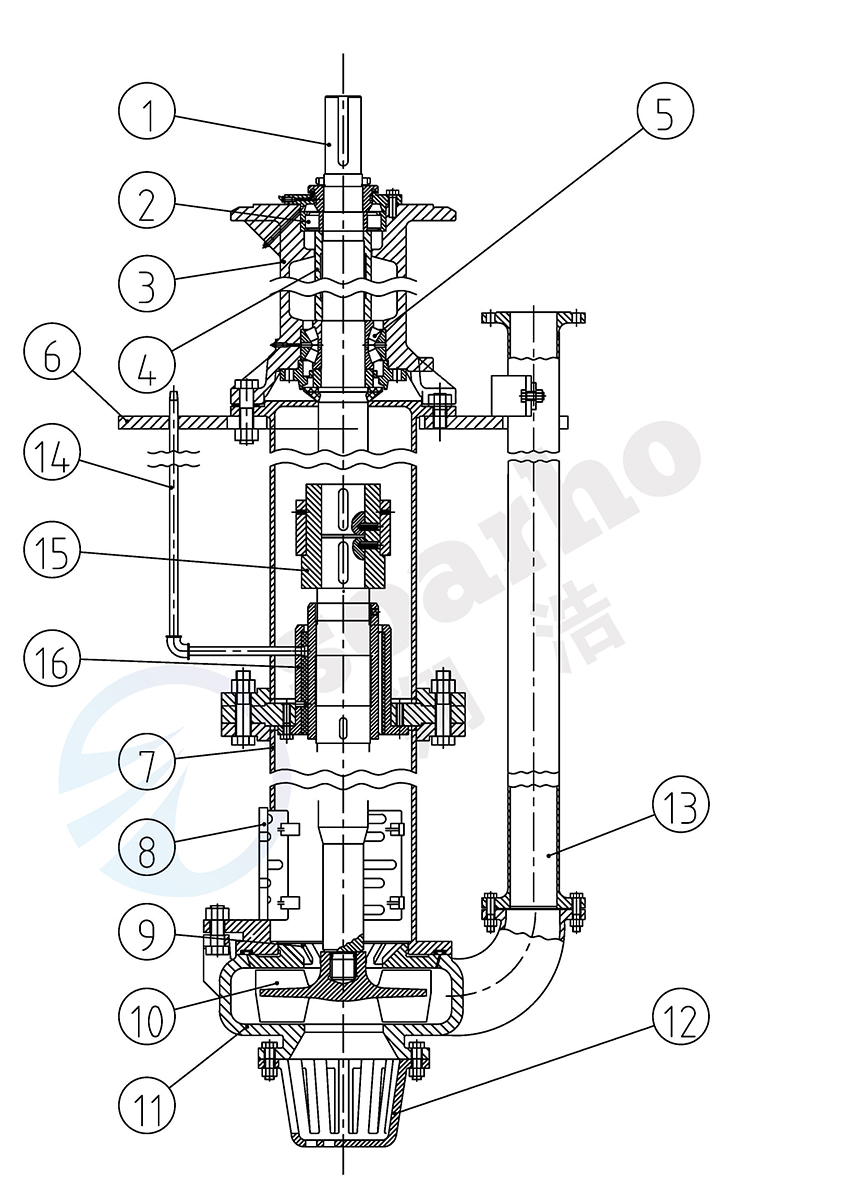

1 Shaft 2 Cylindrical roller bearing 3 Bearing housing 4 Bearing spacer

5 Double row center conical roller bearing 6 Mounting plate 7 Column support

8 strainer 9 Rear liner 10 Impeller 11 Pump casing

12 Lower strainer 13 Discharge pipe 14 Flushing pipe 15 Coupling part

16 Middle supporting part

• Range of PerformanceCapacity 108~479.2m3/h

Head 8.5~40m

Discharge diameter: 150mm

• Drive Type

• Type Of Pump Inlet Construction

• Outline Drawing

Related Keywords