SMSP65-QVL Lengthening Sump Slurry Pump

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean

- Port:

- Tianjin In China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shijiazhuang |

|---|---|

| Supply Ability: | 20 Set/Month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Transportation: | Ocean |

| Port: | Tianjin In China |

SMSP65-QVL Lengthening Sump Slurry Pump

• Product Introduction

SMSP65-QVL lengthening sump slurry pump is SP sump slurry pump with extended shaft which is suited for the working condition of deeper level. This vertical centrifugal slurry pump design with hard metal components makes it ideal for large particle size, continuous or [snore" operation and high density slurries. Applications of this metal sump slurry pump include: coal preparation, chemical handling, minerals processing, sand and gravel and general tank, pit or hole-in-ground slurry applications. This type single casing sump slurry pump has high interchangeability with Warman slurry pump, which is built from high chrome cast iron. This vertical centrifugal sump slurry pump is available in various standard lengths to suit common sump depths. A suction extension pipe can be fitted to the bottom inlet to extend the depth of the pump by up. Even if the top inlet is not submerged, the pumping maintained.

•Type Notation:

For example: SMSP(SPR)150-SV(L) (SP: SP series Sump Pump; SPR: Rubber Lined Sump Pump;150: Discharge Diameter (mm); SV: Frame Type; L: Extension Type.)

• Product Feature

1. Vertical, centrifugal and single-casing structure.

2. Heavy duty roller bearings, above mounting plate.

3. The impeller is open structure, be made of high chromium white iron.

4. No submerged bearings.

5. No shaft sealing problems.

6. The lengthened shaft series of mud sump slurry pump could be applied to the condition of deep liquid level. It lengthens the shaft and adds the guide bearing on the basis of the standard pump, making its operation more stable and application more extensive, but flushing water should be attached to the guide bearing.

7. Construction of pump inlet is available in three types: standard type with strainer, suction type with strainer, with agitator.

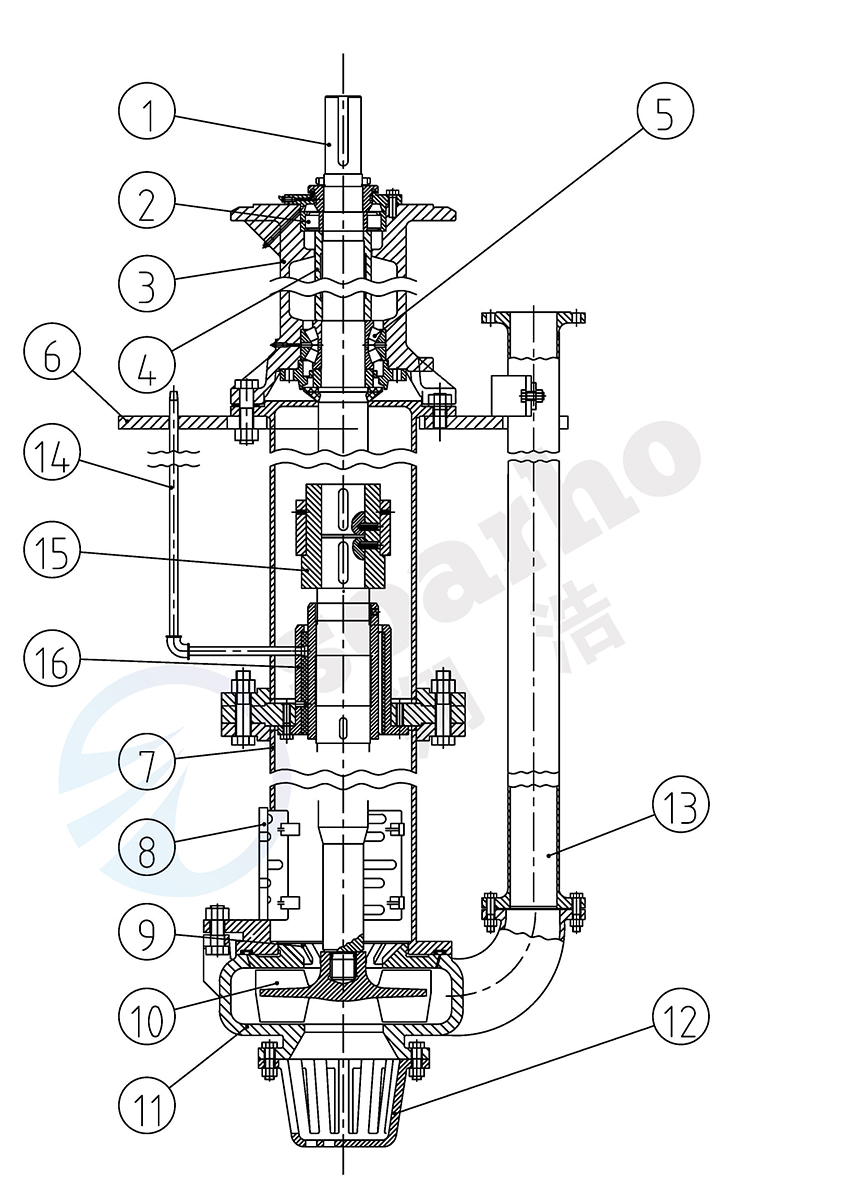

1 Shaftl

2 Cylindrical roller bearing

3 Bearing housing

4 Bearing spacer

5 Double row center conical roller bearing

6 Mounting plate

7 Column support

8 strainer

9 Rear liner

10 Impeller

11 Pump casing

12 Lower strainer

13 Discharge pipe

14 Flushing pipe

15 Coupling part

16 Middle supporting part

• Range of Performance

Capacity 23.4~111m3/h

Head 5~29.5m

Discharge diameter: 65mm

• Drive Type

• Type Of Pump Inlet Construction

• Performance Curves

• Outline Drawing

Related Keywords