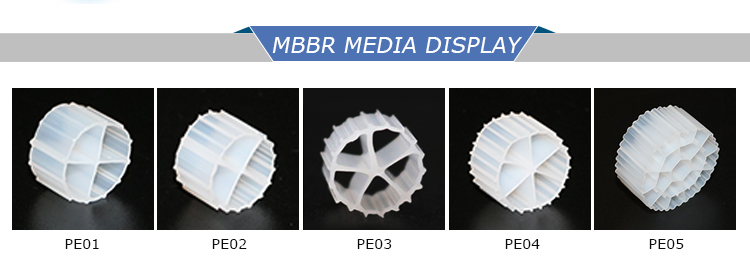

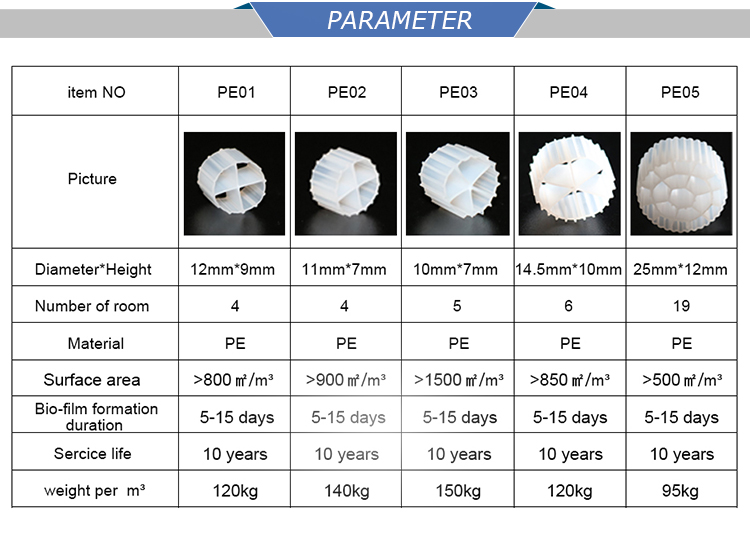

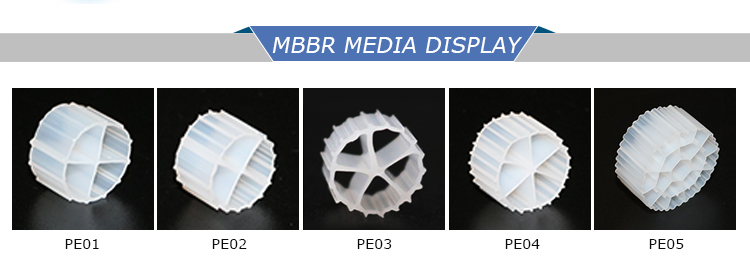

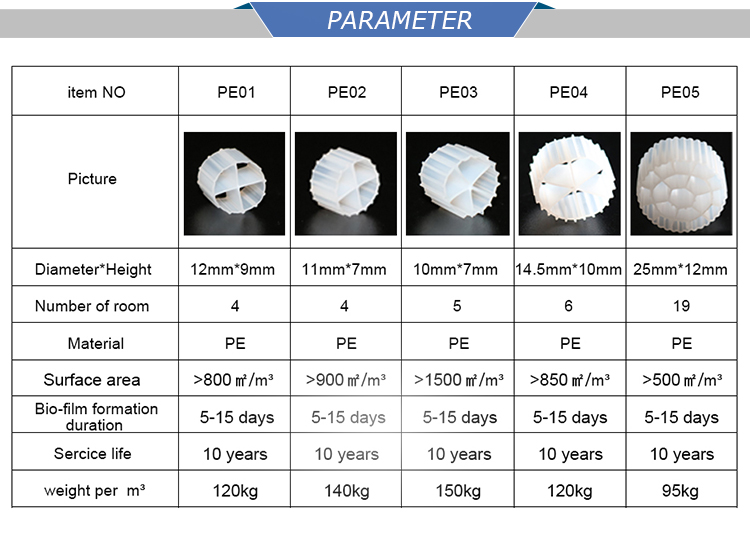

The MBBR process takes place in a basin, also known as a reactor or as an aeration tank.Their design maximizes the surface area they provide for biofilm to grow on them. Many carriers resemble rotelle, or wheel-shaped, pasta. They mimic the density of water, allowing them to mix throughout the fluid, rather than floating or sinking.

* Rapid carrier bio film formation mechanism

* Super decarburization, ammonia nitrogen removal capacity

* Excellent resistance to shock load performance

* Flexible way of engineering application

* Simple operation and maintenance

* Long service life-100% virgin HDPE material.

* Deoxidation and phosphorus removal effect is good