AD Star Calcium Carbonate Packaging Bag

- Payment Type:

- L/C, T/T, D/P

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 20000 Bag/Bags

- Min. Order:

- 20000 Bag/Bags

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Tianjin, Qingdao, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 3000,000pcs per month |

| Supply Ability: | on time delivery |

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,FCA |

| Certificate: | ISO9001, BRC, Labordata, RoHS |

| HS Code: | 6305330090 |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin,Qingdao,Shanghai |

A large percentage of PP woven bags – 30 to 40 percent is produced with coating, this number is kept on rising this couple of years. Because coated sacks

provide much better protection of the contents from dust and especially from

moisture. Coated fabric also offers better printability.

Refer to the industrial packaging, a coated or bopp laminated woven bag plus the AD Star bag making machine, bring big benifits for the cement, putty, limestone, food ingredient... powdery materials.

Technical of the AD*Star Block Bottom Valve PP Woven Bags

1. Hot air Welding, no stitch, no hole, no adhesive.

2. More Environmental protection.

3. Production capacity may get 1.5 million per week.

4. Star micro perforation system

AD*STAR® is the well-known sack concept for cement - in use worldwide, patented internationally, and produced exclusively on Starlinger machines. The brick-shaped PP woven sacks, produced without adhesives by heat-welding of the coating on the fabrics, was developed with automated filling and landing processes in mind. As a result of the material characteristics and the special production process, the weight of an average 50 kg AD*STAR® cement sack can be as low as 75 grams. A comparable 3-layer paper bag will weigh about 180 grams and PE-film bag 150 grams. An economical use of raw material not only helps minimize cost, it is also a valuable contribution to the preservation of our environment.

The Ad*Star Sack can be produced either as a one-layer block bottom valve bag (V-BB) or as an open mouth bag with a block bottom without valve (OM-BB) and with or without micro-perforations.

Fabric Construction - Circular PP Woven fabric (no seams) or Flat PP

woven fabric (back seam bags)

Laminate

Construction -

PE coating or BOPP Film

Fabric

Colors - White, Clear,

Beige, Blue, Green, Red, Yellow or customized

Printing - Off-set print, Flexo print, gravure

print.

UV

Stabilization -

Available

Packing - 5,000 Bags per Pallet

Standard

Features - No stitching,

completely hot welding

Optional Features:

Printing Anti-slip Embossing Micropore

Valve extendable Kraft paper combinable Top opened or valved

Sizes Range:

Width: 350mm to 600mm

Length: 410mm to 910mm

Block width: 80-180mm

Weave: 6x6, 8x8, 10x10, 12x12, 14x14

Our company

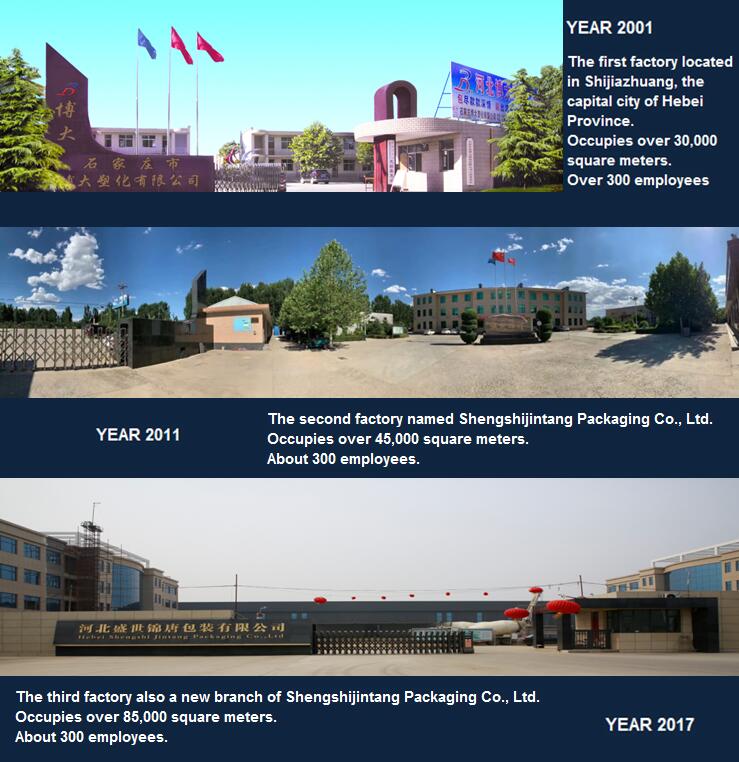

Boda is one of China’s top packaging producers of specialty Polypropylene Woven Bags. With world-leading quality as our benchmark, our 100% virgin raw material, top-grade equipment, advanced management, and dedicated team allow us to supply superior bags all over the world.

Our company covers an area totally of 160,000 square meters and there are more than 900 employees. We possess a series of advanced Starlinger equipment including extruding, weaving, coating, laminating and bag produce. What’s more, we are the first manufacturer in domestic that imports the AD* STAR equipment in the year 2009 for Block Bottom Valve Bag Production.

Certification: ISO9001, SGS, FDA, RoHS

Our main products are: PP woven bags, BOPP laminated woven sacks, BOPP Back seam bag, PP big bag, PP woven fabric

Related Keywords