Metal Angle Iron Roll Forming Machine

-

USD13000≥1 Set/Sets

- Payment Type:

- L/C, T/T, Money Gram

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean

- Port:

- Tianjin Xingang

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Hebei |

|---|---|

| Productivity: | 200 sets/year |

| Supply Ability: | 200 sets/year |

| Payment Type: | L/C,T/T,Money Gram |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | CE/ISO9001 |

| HS Code: | 84552210 |

| Transportation: | Ocean |

| Port: | Tianjin Xingang |

Metal Angle Iron Roll Forming Machine

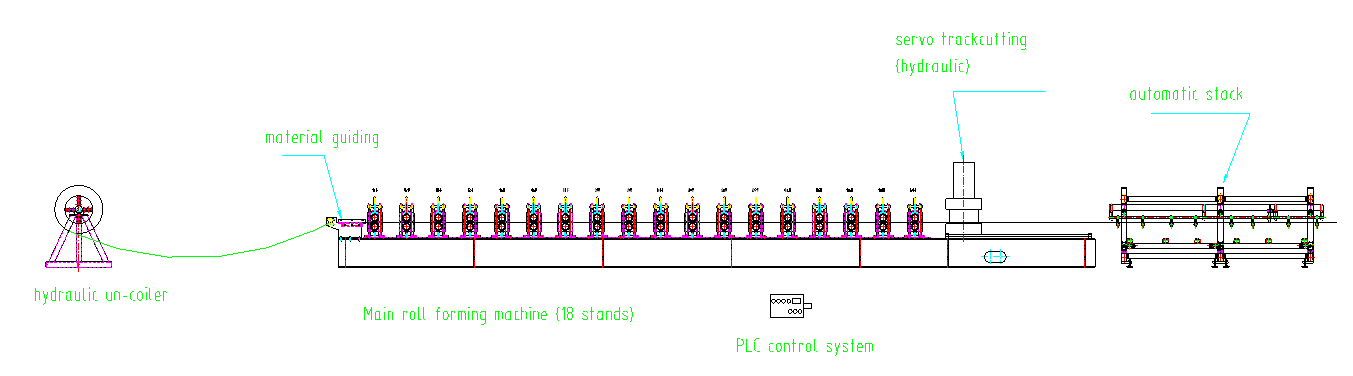

Working process:

Decoiler - Feeding guide - Straighteing - Main roll forming machine - PLC control system - Servo tracking cutting - Receiving table

Technical parameters:

|

Raw material |

PPGI, GI, Aluminum coils |

|

Material thickness range |

0.3-1mm |

|

Forming speed |

0-45m/min(include punching) |

|

Rollers |

12 rows |

|

Material of forming rollers |

45# steel with chromed |

|

Shaft diameter and material |

40mm, Cr12 |

|

Controlling system |

PLC |

| Cutting mode | Servo tracking cutting |

|

Material of cutting blade |

Cr12 mould steel with quenched treatment |

|

Voltage |

380V/3Phase/50Hz or at your requirement |

|

Main motor power |

5.5KW |

|

Hydraulic station power |

3KW |

|

Way of driven |

Gear |

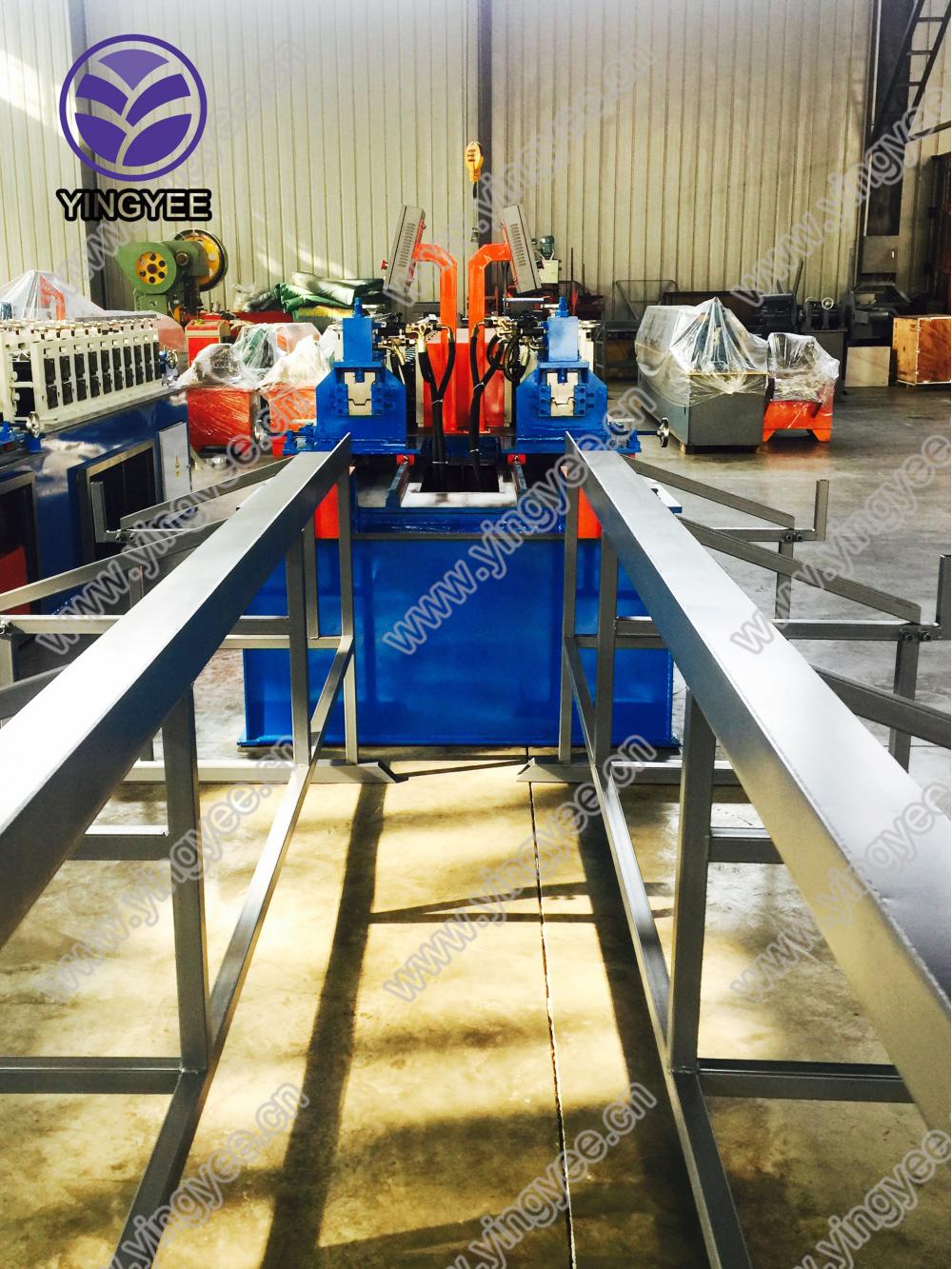

Pictures of machine:

Company information:

YINGYEE MACHINERY AND TECHNOLOGY SERVICE CO.,LTD

YINGYEE is the manufacturer specialized in various cold forming machineries and automatic production lines. We have a wonderful team with highly technology and excellent sales, which offer professional products and related service. We paid attention to quantity and after service, got great feedback and honor formal the clients. We have a great team for after service. We have sent several patch after service team to oversea to finish the products installation and adjustment.

Our products were sold to more than 20 countries already. Also included US and Germany.

Main product :

- Roof roll forming machine

- Roller shutter door roll forming machine

- C and Z purlin roll forming machine

- Downpipe roll forming machine

- Light keel roll forming machine

- Shearing machine

- Hydraulic decoiler

- Bending machine

- Slitting machine

FAQ:

Training and Installation :

1 We offer installation service local in paid, reasonable charge.

2 QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service:

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period

2. Effective communication

3. Interface customized.

Related Keywords