Drywall metal stud and track roll forming machine

-

$30000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean

- Port:

- TIANJIN XINGANG

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 100 Set/Sets per Year |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Transportation: | Ocean |

| Port: | TIANJIN XINGANG |

2. Running speed: 0-12m/min.

3. Main shaft material: 45# steel, Q&T treatment

4. Main axis diameter: 75mm

5. Roller material: GCr15 bearing steel, Qunching heat treatment, surface black finish. Rigidity:HRC58-62.

6. Roller groups: 15 groups main rollers

7. Levelling roller: 7 rollers levelling device

8. Main motor power: 11KW;

9. Hydraulic station motor power: 5.5KW

10. Punching station: 2 punch device

11. Electrical control system: Whole line adopted PLC control, Panasonic PLC.

12. Cutting method: Hydraulic powered, automatically cut to length after roll forming

13. Cutting mold material: Cr12 quenching treatment

14. Uncoiling: by 5T Manual uncoiler

15. Machine dimension: 8m L X 0.88 m W X 1.0 m H

16. Machine weight: about 8 tons.

-machine components

One Purlin Forming machine can produce many sizes of purlin .

The line mainly consist of uncoiler , coil sheet guiding device ,flattening device ,roll forming system ,

punching equipment ,cutting equipment , hydraulic station ,PLC controlling system and support table .

Technical Parameters of Light Keel Roll Forming Machine

Shijiazhuang Yingyee Import&Export Co., Ltd.

YINGYEE is the manufacturer specialized in various cold forming machineries and automatic production lines. We have a wonderful team with highly technology and excellent sales, which offer professional products and related service. We paid attention to quantity and after service, got great feedback and honor from all the clients. We have a great team for after service. We have sent several patch after service team to oversea to finish the products installation and adjustment.

Our products were sold to more than 20 countries already. Also included US and Germany.

Main product :

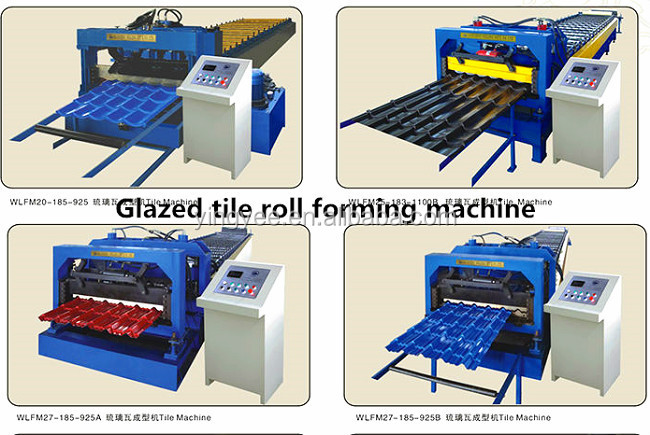

Roof roll forming machine

C and Z purlin roll forming machine

Downpipe roll forming machine

Hydraulic decoiler

Light keel roll forming machine6

Bending machine

Shearing machine

slitting machine

Roller shutter door roll forming machine

Training and Installation

1 We offer installation service local in paid, reasonable charge.

2 QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period.

2. Effective communication

3. Interface customized.

Related Keywords