screw machine made aluminum truss portable stage

-

USD48000≥1 Bag/Bags

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA, CPT

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Tianjin, Shanghai, Qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Hebei |

|---|---|

| Productivity: | 200 sets/year |

| Supply Ability: | 200 sets/year |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA,CPT |

| Certificate: | CE/ISO9001 |

| HS Code: | 84552210 |

| Transportation: | Ocean,Land,Air |

| Port: | Tianjin,Shanghai,Qingdao |

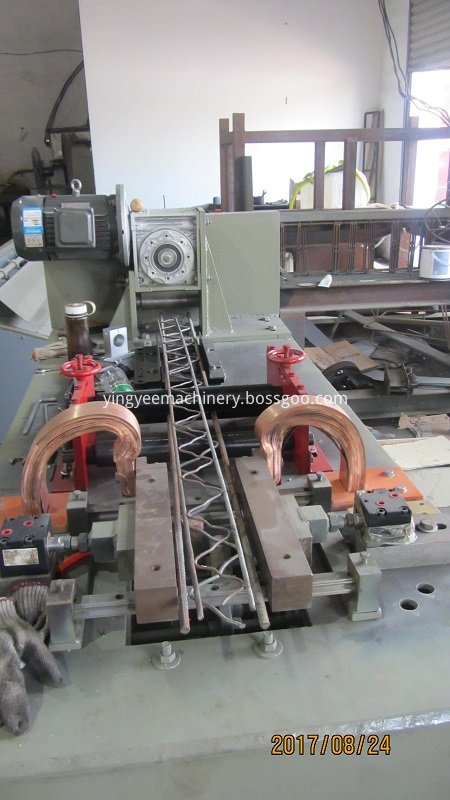

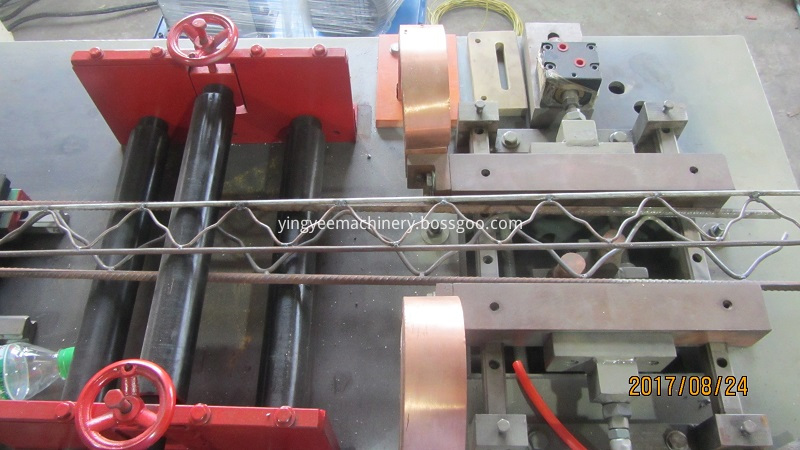

Steel rods truss mesh machine for building

Our TZG series High Precision Welded Pipe&Tube Line with the latest technology, meet high efficiency output, easily operated and stable running performance, also the complete tube mill line meet a high level automation.

This high precision tube mill series with excellent design, selected high precision durable roller under strictly quenching, high performance cutting saw, complete machine body with heat treatment, accurate fabrication, precise assembly.

The machine performance has reached the international ERW welded tube standard. This tube mill series outer diameter range can be from Φ7mm to Φ 50.8mm and wall thickness of 0.2~2.0mm, all these size tubes are produced with large output, best quality and high precision. Our customized machines are also can be used for different processed material and meet nearly all applications.

Production process

|

item |

Spec |

Quality |

|

main machine |

15*12*1.6 m |

1 set |

|

Weight(main machine) |

4 T |

----- |

|

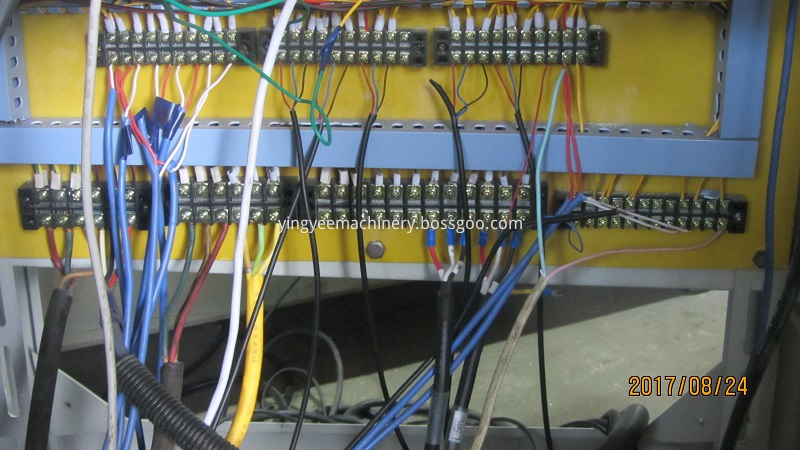

PLC control box |

DELTA |

1 set |

|

Electronic box |

Transfer by electronic |

1 set |

|

Speed |

6 m/ min |

----- |

|

Motor for straighten |

0.75 KW |

3 sets |

|

Servo motor |

3 KW |

1 set |

|

Motor for bending |

3 KW |

1 set |

|

Wielding transformer |

160 K V A |

1 set |

|

Wielding pillar |

---------- |

4 piece |

|

Decoiler for material |

With motor 1.1 kw(3 sets) |

3 sets |

|

Air compressor |

1470 x 520 x 940 mm |

2 sets |

SPARE PARTS

|

Item |

Quality |

|

Wielding machine |

1 set |

|

Pillar |

4 sets |

|

Proximity switch |

10 piece |

|

Air cylinder |

2 units |

|

Magnetic valve |

2 pieces |

|

Oil seal |

10 pieces |

|

Equipment especially tools for butt welding |

1 set |

Company information:

YINGYEE MACHINERY AND TECHNOLOGY SERVICE CO.,LTD

YINGYEE is the manufacturer specialized in various cold forming machineries and automatic production lines. We have a wonderful team with highly technology and excellent sales, which offer professional products and related service. We paid attention to quantity and after service, got great feedback and honor formal the clients. We have a great team for after service. We have sent several patch after service team to oversea to finish the products installation and adjustment.

Our products were sold to more than 20 countries already. Also included US and Germany.

Main product :

- Roof roll forming machine

- Roller shutter door roll forming machine

- C and Z purlin roll forming machine

- Downpipe roll forming machine

- Light keel roll forming machine

- Shearing machine

- Hydraulic decoiler

- Bending machine

- Slitting machine

FAQ:

Training and Installation :

1 We offer installation service local in paid, reasonable charge.

2 QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service:

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period

2. Effective communication

3. Interface customized.

Related Keywords