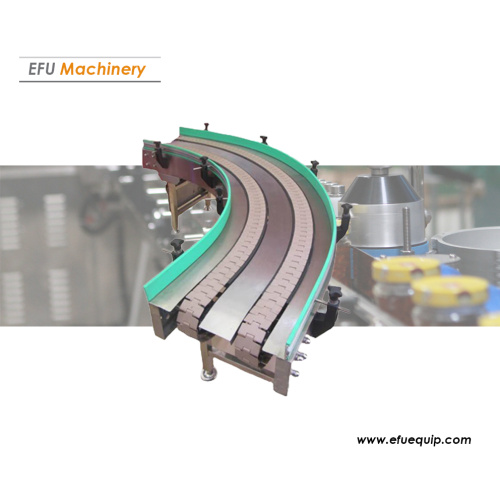

Curved chain plate conveyor

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 10 Days

- Transportation:

- Ocean, Land, Air

- Port:

- TianJin, GuangZhou, QingDao

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW |

| Transportation: | Ocean,Land,Air |

| Port: | TianJin,GuangZhou,QingDao |

Structure and characteristics

The conveying surface of the turning chain plate conveyor is flat and smooth, with low friction, and the material transitions between conveying lines smoothly. It can convey all kinds of glass bottles, PET bottles, cans and other materials, and can also convey all kinds of bags.

Main features

The chain plates are made of stainless steel and engineering plastics, with a wide variety of specifications, which can be selected according to the conveying materials and process requirements, and can meet the different needs of various industries. The conveying capacity is large, and it can carry a large load, such as used in electric vehicles, motorcycles, generators and other industries; the conveying speed is accurate and stable, which can ensure precise synchronous conveying.

Turning chain conveyors can generally be directly washed with water or directly immersed in water. The equipment is easy to clean and can meet the hygienic requirements of the food and beverage industries. Flexible equipment layout. It can complete horizontal, inclined and turning conveying on one conveying line. The equipment has simple structure and easy maintenance.

The chain plate conveyor uses the standard chain plate as the bearing surface and is driven by the motor reducer; we can use multiple rows of chain plates in parallel to make the chain plate conveyor very wide and form a differential speed, using the speed of multiple rows of chain plates The difference makes multi-line conveying become single-line conveying without squeezing, so as to meet the requirements of single-line conveying for beverage labeling, filling, cleaning and other equipment.

It is also possible to change a single row into multiple rows and walk slowly, thereby generating storage capacity, which can meet the requirements of large-scale feeding of sterilizers, bottle storage stations and cold bottle machines. We can make the head and tail of the two chain conveyors The overlapping mixing chain makes the bottle (tank) body in a dynamic transition state, so that no material is retained on the conveyor line.

Material:

Carbon steel, stainless steel, thermoplastic chain, chain plates of different widths and shapes can be selected according to your product needs to complete the requirements of flat transportation, flat turning, lifting, and lowering.

Specification and Application:

Vodel:CB-C

The width of the straight chain plate is 63.5, 82.5, 101.6, 114.3, 152.4, 190.5, 254, 304.8;

The width of the turning chain plate is 82.5, 114.3, 152.4, 190.5, 304.8, which is widely used in the automatic conveying, distribution, and packaging of food, cans, medicines, beverages, cosmetics and detergents.

Related Keywords