Industrial vacuum meat bowl cutter

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- Tianjin, Qingdao, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 100sets/month |

| Supply Ability: | 100set/month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | ISO |

| HS Code: | 84385000 |

| Transportation: | Ocean,Land |

| Port: | Tianjin,Qingdao,Shanghai |

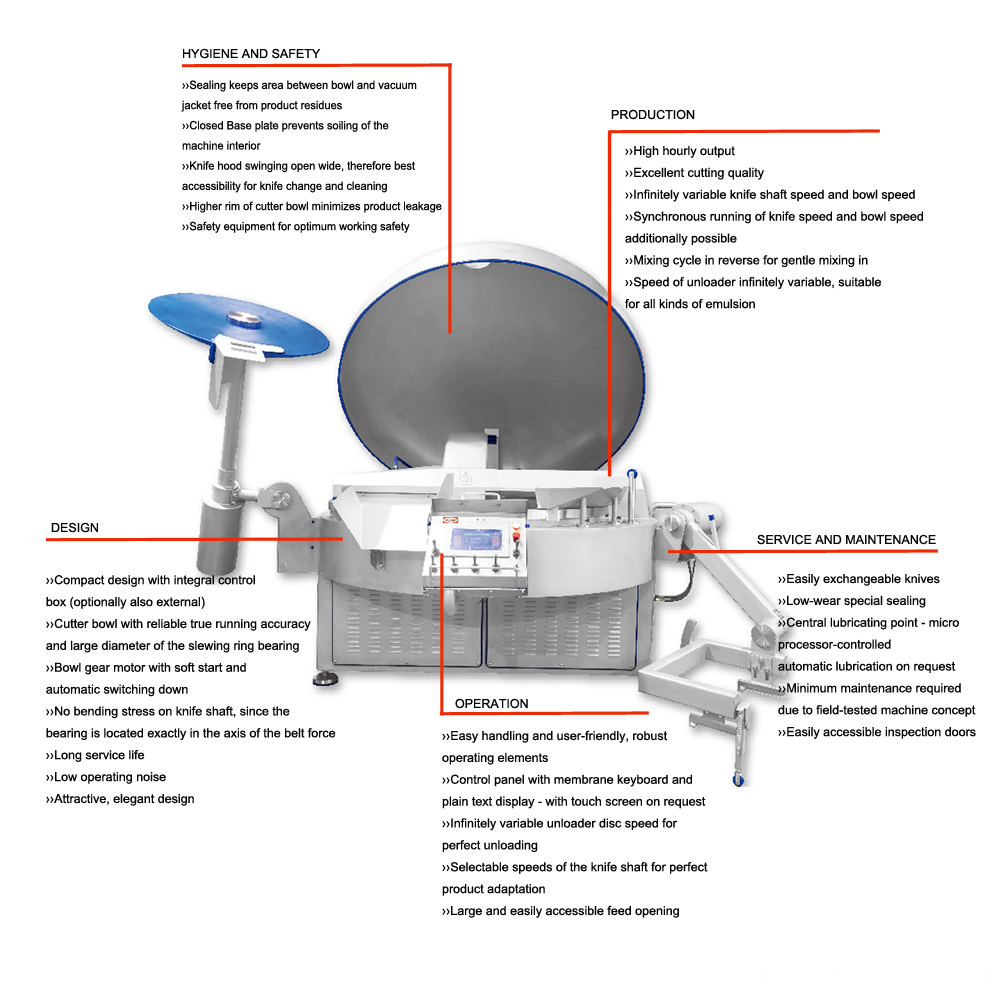

The structure of our stainless steel Industrial Vacuum Bowl Cutter is generous and beautiful, easy to clean, and the design is reasonable. Our meat bowl cutter can ensure that the chopping fineness of meat products, small heating, short cutting time, increasing the flexibility and production rate of the product. Widely used in deep processing of meat, vegetables, seafood, etc. In the vacuum state, chopped materials can increase the production rate, reduce bubbles, enhance elasticity, and fully extract protein, fully combine materials with accessories and water, and have good emulsification effects to ensure that the product reaches the best quality. Our cut mixer uses internationally renowned brand bearings. The main shaft is equipped with an automatic lubrication system, and automatic oil injection is ensured to ensure the smooth operation of the whole machine.

Function:

- ZKZB-750 Bowl Cutter with the function of cutting meat block into grains with different sizes, or meat mud. Vegetable, mushroom, agarics, shallot and ginger etc.can also be cutted, mixed, emulsified.

- Mixing minced meat,seasoning, additive together.

- Ideal combination of knife rolling speed, bowl rolling speed, the reasonable 2mm distance between knife and bowl, good degree of fitness, little tempreture rising and reduced cut time.

- Rubber bar to prevent material leaking during cutting and washing.

- The machine is made by stainless steel, easy to clean, good-looking, endurable, meeting the requirement of food sanitation

Technical parameter of Vacuum Meat Bowl Cutter

|

Model |

Volume |

Capacity |

Knife speed |

Bowl speed |

Power |

Weight |

Dimension |

|

ZKZB-200 |

200L |

170kg/batch |

200/1500/3000/3600r/min |

Frequency |

84kw |

4000kgs |

2950*3060*3130mm |

|

ZKZB-330 |

330L |

260kg/batch |

200/1500/3000/3600r/min |

Frequency |

104kw |

5500kgs |

3240*2870*2650mm |

|

ZKZB-550 |

550L |

450kg/batch |

200/1500/3000/3600r/min |

Frequency |

130kw |

6500kgs |

3710*3060*3130mm |

|

ZKZB-750 |

750L |

650kg/batch |

200/1500/2700/3000r/min |

Frequency |

184Kw |

9000kgs |

3900*3150*1950mm |

|

ZKZB-850 |

850L |

750kg/batch |

200/1500/2700/3000r/min |

Frequency |

224kw |

10000kgs |

3950*3220*3360mm |

|

KNIFE SHAFT Specially developed bearing technology and sealing for highest speeds and high operating safety Low-wear special sealing No bending stress on knife shaft

Long service life of bearings and sealing |

|

HIGH QUALITY KNIFE Standardized knife length;Cost-efficient and easy to maintain;Knife exchange without dismantling of knife head possible |

|

|

JOYSTICK Blind operation;Hygienic design;Easy operate |

|

AUTOMATIC LOADING SYSTEM More Powerful;more stable |

|

|

ELECTRONIC EQUIPMENT Compact, hygienic design due to built-in control box that can be swivelled out to ensure perfect access for maintenance |

Application of Vacuum bowl cutter

Related Keywords